A comprehensive guide on all stages of chainsaw maintenance, with lots of useful tips on what needs to be done.

A guide to the main steps and operations in Chainsaw Maintenance.

Regular and correct maintenance of the chainsaw is essential to maintain optimal and long-lasting cutting performance.

In this guide, we will provide a complete overview of all necessary maintenance work, the aspects to be considered and the most correct procedures to be followed.

CONTENTS

Maintenance stages

Depending on the model, this category of equipment can be used in almost all seasons, from spring for pruning branches with the appropriate pruning chainsaws, to autumn for cutting wood for the winter.

Being used throughout the year, constant maintenance of all machine components and the cutting system is essential.

We can thus summarise chainsaw maintenance in 3 different stages:

- Before and after each use maintenance;

- Routine maintenance;

- Non-routine maintenance in case of a prolonged standstill.

1. Before and after each use maintenance

This first chapter discusses all those operations to be performed immediately after the cutting sessions, both before and after each use of the machine, so for the most part these include checking and inspecting all the various parts as well as cleaning.

| Work to be carried out prior to cutting | Work to be carried out after cutting |

| Visual inspection of componentsi | Cleaning the chainsaw and removing wood shavings and dust |

| Throttle control test | |

| Chain condition check | |

| Checking that the tank and fuel caps are sealed |

1.1 Visual inspection of components

Check that all components are intact and that the guide bar, chain and chain brake are fitted correctly before using the chainsaw.

1.2 Throttle control test

Test the throttle control and all controls connected to it, i.e. throttle lock, air control and stop switch, before use.

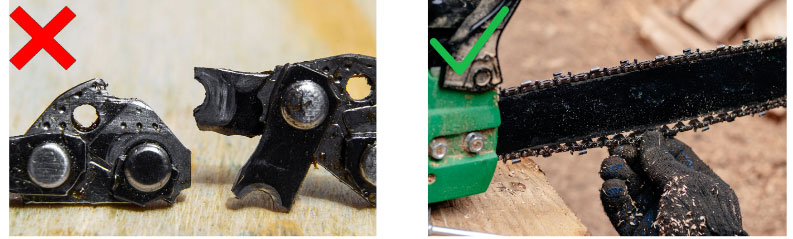

1.3 Chain condition check

One of the most important tasks at this stage is undoubtedly checking the condition of the cutting chain.

By checking we mean both a visual check of its integrity as well as the correct state of sharpening and tensioning, which is essential to achieve good cutting performance and not to damage the cutting bar.

1.4 Checking that the tank and fuel caps are sealed

It should always be checked, as a matter of safety, that all tank caps are closed.

This check is important precisely to avoid dangerous fuel and oil spills during cutting, which especially at high temperatures could be very dangerous.

1.5 Cleaning the chainsaw and removing residues

With each use, the chainsaw is put to the test, wood residue and resin can stick to the bar, the chain becomes dull and the various components wear out.

For all these reasons, it is essential to clean the machine after each cutting session so that it is always in top condition and its cutting performance is maintained over time.

Check that the cooling air slots are clean; if not, clean them with a brush or compressed air jet.

Clean the surrounding area as well to prevent the engine from overheating.

In the case of stubborn dirt, a suitable solvent can also be used. Regular cleaning also helps to prevent bar and chain wear, which is why it is important to disassemble them and remove any residual oil or dirt.

2. Routine maintenance

This section deals with all the work involved in the routine maintenance of chainsaws, i.e. all the work that needs to be performed on a regular basis:

- Checking the air filter;

- Checking and/or replacing the spark plug;

- Checking and/or replacing the fuel filter;

- Checking and cleaning the muffler;

- Checking the condition of the outer casing.

2.1 Checking or replacing the air filter

The air filter prevents dirt and debris from entering the chainsaw.

Its regular, periodic inspection for wear and cleanliness is essential for the proper operation of the machine and for extending its service life.

If the filter is old or damaged, it must be replaced immediately with a new, clean one

If, on the other hand, the filter is in good condition and does not need to be replaced, simply clean it with degreaser and water and then dry it by blowing it with compressed air..

Advice: To clean the air filter, blow with compressed air from the inside out, so that no residue is left behind.

How to clean the air filter?

Checking and cleaning the air filter requires specific steps, which vary depending on whether the filter is made of foam or paper.

Let’s look at the main steps and difference for both filters.

Foam filter:

- Remove the protective cover above the filter;

- Wash the filter with soap and water;

- Dry it with a clean cloth or better, with a jet of compressed air, to remove any excess oil as well;

- Finally, remount the filter and protective casing.

Paper filter:

- Remove the protective cover above the filter;

- Lift the latch that holds the filter in place;

- Clean it with a jet of compressed air;

- Reassemble it, ensuring that it is correctly positioned within the unit.

2.2 Checking or replacing the spark plug

Regularly checking the condition and cleanliness of the spark plug is important for the proper operation of the chainsaw and its engine.

During the inspection, check whether the spark plug only needs to be cleaned or replaced.

Once it has been verified that the spark plug is dirty but still in good condition, proceed with its cleaning.

In this case you will need:

- Protective gloves;

- Wire brush;

- Combination spanner, for removing and checking the spark plug.

How to clean the spark plug?

First you have to find out where it is located, since each chainsaw is built differently; once found and removed, you can proceed to the clean-up process.

Scaling must be removed with the wire bristle brush, scrubbing the area around the electrodes thoroughly as well. For a more thorough cleaning, wrap the park plug in a cloth moistened with petrol to remove further micro residues.

Once it has dried completely, place it back in its housing.

2.3 Checking the fuel filter

Firstly, the fuel filter must be removed from the filler neck of the tank where it is housed.

Then, depending on its condition, it can be either cleaned or not, using a brush, perhaps soaked in petrol, or with the help of compressed air.

Once cleaned, place it back in the filler neck.

2.4 Checking and cleaning the muffler

Check the condition of the muffler regularly and clean it to avoid starting problems.

If it is not too dirty or encrusted, use a rag soaked in petrol or a high-quality degreaser.

If, on the other hand, there is stubborn dirt and encrusted residue, heat it first, so that combustion causes the residue to harden, which can then be removed more easily with the help of a screwdriver.

3. Non-routine maintenance in case of a prolonged standstill.

This chapter, in turn, looks at all the maintenance work and precautions to be taken in case of prolonged standstill of the chainsaw.

The interventions to be done can be resumed as follows:

- Empty the tank and the chain oil pump circuit;

- Remove the spark plug;

- Dismantle and clean the chainsaw thoroughly;

- Store the chainsaw.

3.1 Emptying the tank

First, empty the entire tank and pour the fuel into a suitable container in a sheltered and adequately ventilated place.

Fuel, in fact, tends to deteriorate if left for a long time, which then creates problems for the engine and carburettor.

This being done, clean the tank and empty the carburettor.

After emptying the tank, start the saw and leave it running until the petrol runs out and the machine shuts down.

This prevents the membrane from sticking to the carburettor.

Advice: After draining the tank, pour in 1/4 tank of 15 W40 oil before starting the chainsaw. Start the machine once done, so the oil cleans the tank of all remaining old oil.

3.2 Removing the spark plug

Before storing the chainsaw for a long period of time, it is recommended to remove the spark plug from its housing and not to leave it plugged in.

Advice: Having unscrewed the spark plug, pour a teaspoon of oil into its housing, so that it is not exposed to the air and is always well lubricated.

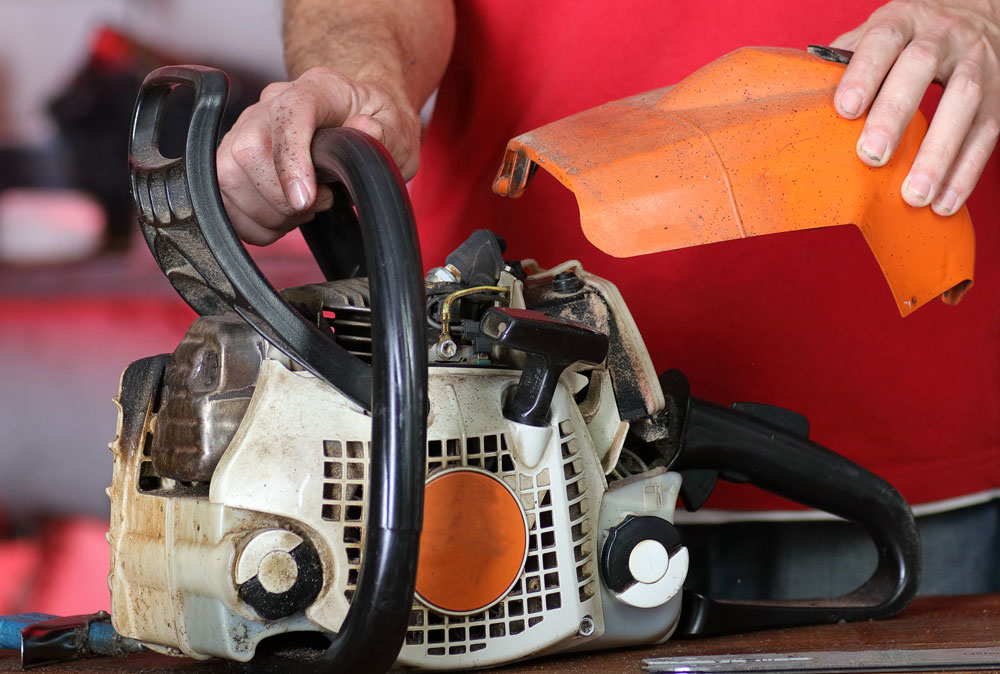

3.3 Disassembly and cleaning

We have already seen in the first chapter on cleaning before and after each use, how important it is to clean the chainsaw and its various parts regularly after each cutting session in order to maintain proper functionality over time.

Before storing the chainsaw for a long period, from three months onwards, however, the machine must be disassembled and thoroughly cleaned in order to be stored and maintained properly.

The steps of this stage can be resumed as follows:

- Cleaning and resharpening the cutting unit: Remove the bar and chain from their housing for thorough cleaning. Remove oil residues and dirt from the oil drain line and inlet hole.

- Cleaning the housing: Remove dust and any sawdust from the housing.

Clean the area around the spool and check that the cooling air slots are clear, if necessary use compressed air or a brush for cleaning. - Topping up the lubricating oil tank: During this stage, add fresh lubricating oil. If any damage is noted inside the tank during this stage, contact a specialist technician to repair it properly.

- Cleaning the oil duct: Check the oil tank level. When using a chainsaw, the oil level decreases, which is completely normal and a sign that it is working properly.

Otherwise, there could be a fault in the lubricating oil supply system.

3.4 Storing the chainsaw

Finally, the last step before leaving your chainsaw in storage for a long time is to store it in a suitable place, protected from sun, dust and weather.

The place where we leave it must be dry, ventilated and protected from the weather, and it is obviously not recommended to leave it in the open,

because just like water and wind, prolonged exposure to the sun can also cause damage to the machine.

4. Maintenance tools

What tools are needed to properly perform all the maintenance tasks listed in the previous chapters?

- Specific chain oil;

- Mixture oil;

- Sharpening set;

- Chain sharpener;

- Replacement spark plug.

In order to perform all the various maintenance steps we have seen in the previous chapters, specific elements are required.

1 – For proper lubrication of the chain, always have a specific lubrication oil available.

2 – Besides lubricating the cutting unit, it is also essential to maintain an adequate sharpening condition, which is precisely why complete sharpening sets are commercially available, including: round file guide, round file, sharpening template and flat file.

3 – An alternative to the manual sharpening set can be a professional chain sharpener.

With this machine you can sharpen the sharp links of the chain without disassembling it.

4 – Moving on from lubrication to the engine, it is necessary to have professional oil for preparing the mixture, which is especially useful for the first starts and running-in of the engine.

5 – One or more spare spark plugs always ready in case of failure or replacement during routine maintenance of the machine.

5. Maintenance clothing

The chainsaw is a very useful and versatile tool that performs various cutting operations to the best of its ability, however, it is a delicate and dangerous tool to use, which is why it is very important to wear the appropriate protective equipment both when working and during maintenance.

Quite often the proper clothing is overlooked for this stage because it may be mistakenly thought that handling the chainsaw when it is switched off is not necessary, but here as well, it is necessary to wear safety clothing according to the various operations carried out.

For maintenance, the main clothing pieces are protective gloves and goggles as well as a mask.

When cleaning the various parts, lingering dirt, wood or resin residues can be found, so wearing gloves and goggles will help you avoid getting dirty or incurring possible irritations and allergies from dust.

The mask, on the other hand, prevents you from inhaling petrol gases during various operations.

On top of this, protective clothing is also required for the various cutting operations.

These are essential for working safely and optimally, if you wish to explore this in more detail please refer to our chainsaw purchasing guide.

6. Frequently asked questions from our customers

Change the chain if the links no longer fit correctly into the bar, if one of the cutting teeth is broken or bent.

Excessive accumulation of dirt on the chain can ruin the it.

White smoke indicates that there is condensation inside the chainsaw that is overheating.

When the engine power level is low or when starting becomes difficult.

There is a risk of an overly worn electrode breaking and puncturing the piston crown.

Synthetic oil is a modern alternative to mineral oil.

The correct mixing ratio is always indicated in the product manual.

An overly oily mixture leads to excessive smoke from the exhaust, formation of deposits on the spark plug and in the combustion chamber.

The chainsaw makes a crooked cut when the chain is blunt or damaged.

Intensive and professional use requires a displacement of more than 45 cc.