A comprehensive guide to purchasing the best harvester, where we focus on the differences between the various types of machines so you can choose the most suitable one for your needs.

The Guide to Choosing the Best Olive Harvesters and Shakers

Complete and Edited by Real Olive Harvesting Machinery Experts

Olive harvesters and shakers are useful hand tools to speed up olive harvesting. The harvester can also be effective in harvesting some types of nuts, such as almonds, walnuts or hazelnuts. There are different models, adaptable to all conditions.

In this guide we will focus on the differences among the different types of machine in order to better choose the one that best suits every single need. This is because there are many varieties of olive trees and, consequently, of olives:

- Olive trees differ mainly by cultivar (i.e. variety), but also by pruning method and age. For example, it is possible to find very tall centuries-old trees with thick foliage or young olive trees featuring a small size but with highly thick foliage;

- The olives are characterised by different size and hardness to detach from the branch depending on the cultivar. These factors are obviously also affected by the level of ripeness of the fruit.

CONTENTS

1. Introduction

Over the years, more and more people have switched from manual harvesting with a rake to mechanical harvesting with an olive harvester, both to save effort and, above all, to speed up olive collection since the time available to spend on the countryside is always limited, especially for the hobbyist.

Over the years, the machine development has significantly evolved, leading to the creation of professional-level products that are extremely efficient and respect the olive tree. At the same time, shakers were also developed, and even if they are intended for manual use, they act differently. Indeed, unlike the olive harvesters that mainly move the olive branches, the shaker acts directly on the branch.

2. Olive harvesters

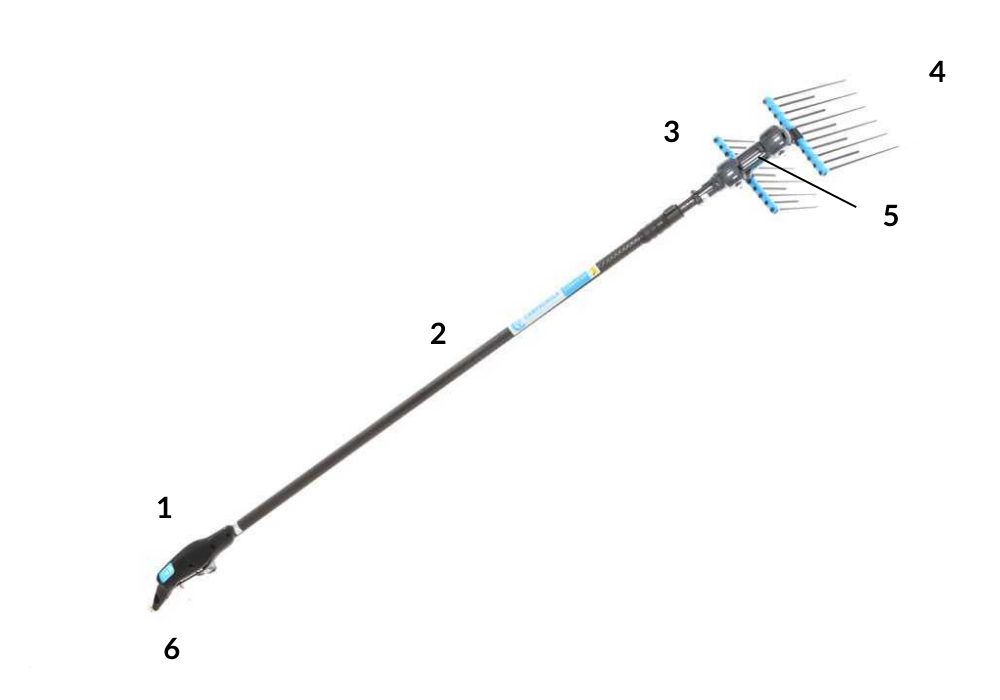

- Engine (it can be placed on top or at the bottom of the pole, for an optimal machine balancing; it can make a difference to the efficiency, harvesting speed and reliability)

- Pole (made of aluminium or carbon, which makes it ultra-light, it can be fixed or telescopic)

- Rakes or combs (there are several types differing for materials, shapes and lengths)

- Prongs (the points on the rake, they can differ according to materials, shape and length)

- Reduction gearbox (defines the harvesting technique depending on the type of machine movement and sturdiness)

- Handle with battery contacts (the connect the olive harvester to a standard 12 V car battery)

There are several types of olive harvesters that can be classified according to their movement, materials or components. Here follows a list of the different models of olive harvesters categorised according to their type of power supply.

3. Electric olive harvesters

Electric olive harvesters are the most popular as they do not need any other equipment to operate, except a battery. There is a wide selection, ranging from the hobbyist to the more efficient and professional ones used even for large olive harvests.

The main difference lies in the operating method and the way in which the harvester acts on the olive tree: shaking the branch or acting directly on the branches and olive (combing). This is given by the type of movement of the combs, which can be:

Movimento verticale

Horizontal motion

Side tilting motion

Swinging motion

Horizontal tilted motion

Rotary motion

Double rotary motion

3.1. Vertical motion

The vertical motion is best suited for olive trees with the fronds pointing downwards and with good internal pruning of the plant, i.e. without second-order branches.

It is suitable for the more stubborn and smaller types of olive (e.g. moraiolo or rosciola) since its motion directly affects the fruit.

The operator’s manoeuvring is very simple as they move from top to bottom, working on the fronds. Normally, the rake is shaped to fit olives of different sizes.

3.2. Horizontal motion

Horizontal movement catchers can be either double-rake or double-arm. They are best suited to plants with even superficial external trimming but with airy internal pruning, predominantly with the large olive type, e.g. leccino, and with good ripeness.

Operation is performed by directly shaking the branch until the olive falls off. This is done by placing the prongs in the frond, to exploit the maximum reach of the rakes and the maximum flexibility at the tip of the prongs, which are generally made of carbon fibre.

Horizontal motion

Horizontal side motion

3.4. Horizontal side tilting motion

The single arm harvester with side horizontal tilting motion ensures a very wide reach of the harvesting area. It is placed directly into the frond and creates small rotations on the branch, thereby exploiting the maximum flexibility at the tip of the prongs, usually made of carbon fibre.

Being a one-armed prong holder, it creates higher vibrations compared to similar above-mentioned double-armed prong models, and ensures an even grip of all prongs on the branch.

It is best suited for varieties such as leccino and suchlike, with large, well-ripened olives.

3.3. Swinging motion

The swinging motion also allows the harvester to perform a shaking action on the branch: this is a direct action on the frond, caused by the concentric rotation of the axle which supports the 2 prong-holders.

These harvesters are suitable for plants with sparse pruning and should be placed directly on the frond: there is no need to move the harvester from top to bottom, simply place it on the frond with the fruit.

It is suitable for all types of olives, as long as they are ripe.

3.5. Horizontal tilted motion

Harvesters with this type of motion belong to the same family as those with lateral motion, with the difference being that all the prongs are angled towards the branch, so that the operator does not lean towards the branch himself. The prongs are made of carbon fibre and are best suited for a variety such as leccino with a good degree of ripeness.

3.6. Rotary motion

In this type of harvester, the rotary motion of the shaft acts on the support of the prong holder, swinging it. The elliptical motion of the support base creates a strong swing at the top of the prongs that causes a very effective shaking of the branch, but also discrete vibrations that affect the pole of the harvester.

In these models, the prongs do not necessarily create a rake and can be either made of resin, with a gentler action, or of carbon fibre, which is much stiffer and recommended for sturdier olives. They are best suited for trees with dense foliage and little pruning on the inside, as opposed to models with lateral motion.

The rotary motion harvesters are suitable for all types of olives, although it is better if they are well ripened.

Rake with soft prongs -

Rake with carbon prongs

Round head with angled prongs

Round head with carbon prongs

3.7. Double rotary motion

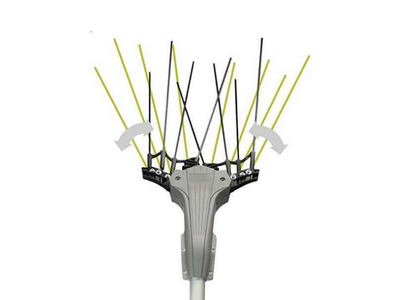

The double rotary motion was invented in order to simultaneously benefit from several motion systems: the lateral and elliptical rotary motion. The rakes move independently and work against each other, so that vibrations affecting the pole of the harvester are reduced to a minimum.

The elliptical rotation of both elements causes the vertical opening and the lateral motion: this causes both a direct shaking of the branch and a direct action on the olive, causing it to fall off.

Since it is the most complete motion system, it adapts to any pruning situation and type of olive, even those that have not reached full ripeness. Again, there are models with resin or carbon prongs.

4. Hobby or professional model

Let us now find out what the main differences are between a hobbyist and a professional model by analysing the different parts that form the harvester.

4.1. Engine

Hobby models are fitted with a brush engine that operates directly via connection to the classic 12-volt car battery and provides a maximum output of around 300 watts. The main downside is that a decrease in battery charge also results in a decrease in performance, with a greater strain on the machine. Additionally, there is a visible drop in motion speed even with a fully charged battery when work requires more effort, e.g. to pass through dense foliage.

Brush engine on the head

Induction engine on the handle

Professional models feature an inverter-controlled digital engine. These harvesters have an inverter control unit whose purpose is to convert the 12-volt voltage of the classic car battery into a higher voltage.

Models with a torque and power management function can also be found: this results in a constant RPM that avoids drops in performance under any conditions of strain or loss of charge. Furthermore, some professional models also include automatic economiser functions that slow down the motion when there is no contact with the frond, thus saving battery power.

Finally, among the best professional harvesters is the option of purchasing a lithium backpack battery, which is very practical in order not to have to move the car battery and its cable each time. It is a compact and very powerful alternative to cope with a full day’s work and can also be used with other equipment in the same line.

Cart with battery

Power generator

Backpack with lithium battery

4.2. Transmission System

The second most important part of a harvester is the transmission from the engine to the rakes. Obviously, in a professional harvester this will be more solid and durable, but the major difference lies in the type of motion it can give the rakes.

As a matter of fact, models with greater harvesting capacity have motion styles that, combined with quality prongs and rake couplings designed for that specific motion, allow the harvester to adapt to all kinds of situations and have a sustained harvesting speed. Besides this, the material of the gearbox is important as well, being robust yet lightweight in the best models to help keep the overall weight of the harvester down.

4.3. Prongs

The prongs are also important as they are designed and adapted according to the type of motion. Besides the option of having different shapes (such as tuning fork rakes that fit every olive size), the professional series also includes modular rakes, with prongs that can be removed and replaced individually according to work requirements or in case of damage.

Another variant between the different models is the material:

- resin ones are less harmful to the plant but tend to warp with use; in any case, replacement is cheap

- carbon ones, which are more suitable for models that shake branches rather than comb them, are generally longer and have the advantage of having a greater harvesting capacity. They do not warp but are more aggressive on the plant.

4.4. Pole

As for the poles, one can switch from the classic aluminium to the lighter carbon, which saves up to three grams in weight: the difference is noticeable, especially at the end of a full working day. Lastly, there is the choice between fixed or telescopic poles: telescopic poles, thanks to their extension system, are convenient for reaching taller branches without using a ladder, however, they are heavier compared to fixed poles.

Aluminium fixed pole

Carbon fixed pole

Telescopic pole extension system

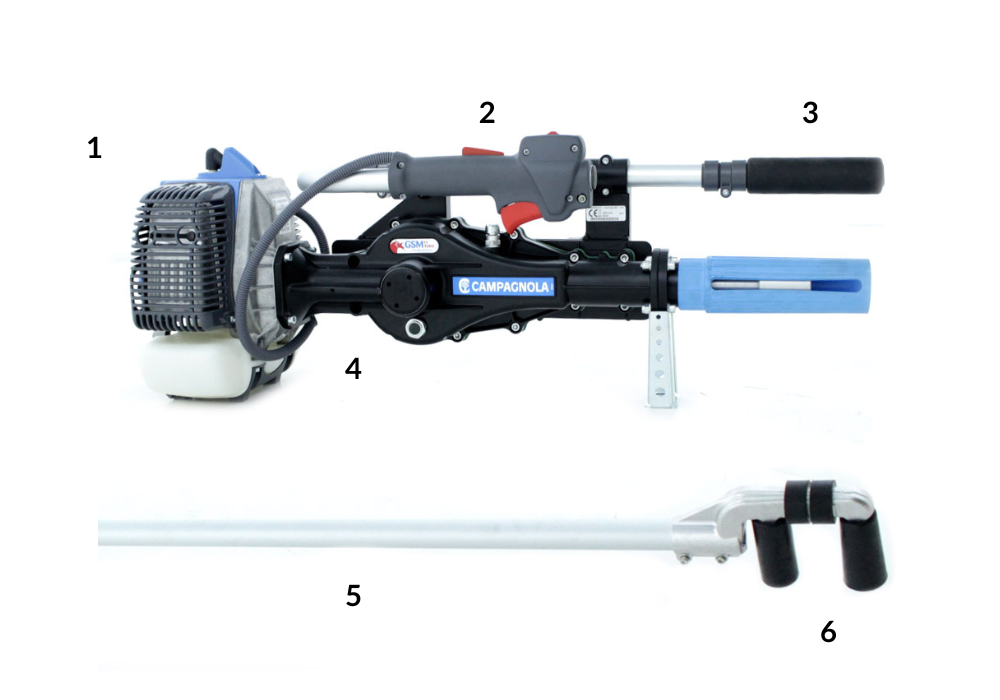

5. Petrol olive harvesters

The petrol-powered versions are very similar to the battery-powered ones with lateral motion, in both professional and hobby models. The main difference obviously lies in the internal combustion engine, which replaces the battery engine and is placed at the base of the pole of the harvester. The downside compared to battery-powered harvesters is that the engine is heavier and louder.

Some models also feature a multifunctional configuration and can therefore become pruners, hedge trimmers or brush cutters.

- Brush cutter

- Hedge trimmer

- Olive harvester

- Pruner

- Extension (for pruner and hedge trimmer)

- Engine

6. Pneumatic harvesters

- COMPRESSED AIR SOURCE: Feeding a pneumatic harvester correctly involves providing a constant, regulated, dried and lubricated air flow. Ordinary electric compressors are not suitable for this, instead it is necessary to use air compressors with a different delivery system that can be either electric, petrol or tractor-mounted, which are convenient to carry in the field.

-

Electric air compressor -

Petrol air compressors -

Tractor-mounted air compressor

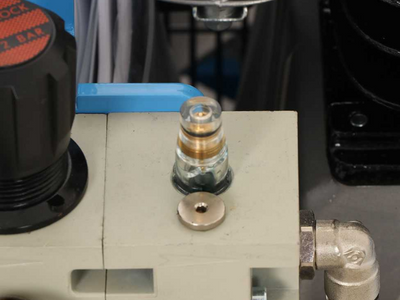

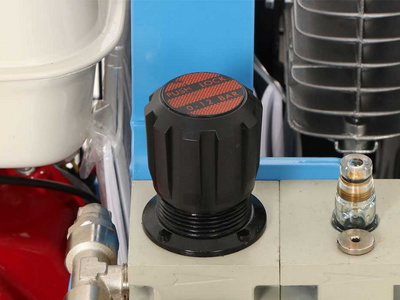

- LUBRICATION: The compressed air that feeds the harvester must be oiled so that it directly lubricates the cylinder of the small motor, in which the piston moves via the forced air flow. Lubrication must be carried out using a specific anti-condensation and anti-freeze lubricating oil. It is loaded into the flow-regulated lubricator of the air compressor and, depending on the model, the amount of oil that is to be mixed with the compressed air is adjusted.

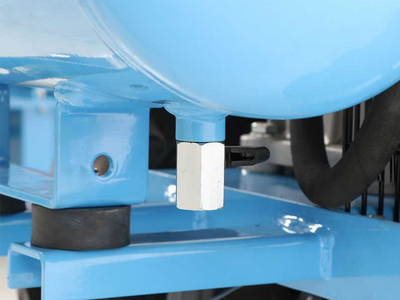

- DEHUMIDIFICATION: The compressed air must also be dry and therefore free of condensation, which could ruin the mechanism of the harvester. Air compressors must therefore have an outlet condensate collector, which must frequently be drained via the appropriate tank valve before connecting the harvester.

Lubricator

Condensation drain valve

- PRESSURE: The outlet pressure must be set within the value required for the correct operation of the harvester, as excessive pressure will damage it. This is even more important when there is more than one harvester connected, and it must be adjusted accordingly. Additionally, it needs to be steady because the harvester would be inoperable if the required value dropped by even a small amount.

Pressure regulator

Pressure gauge

- AIR FLOW RATE: The air flow is also of paramount importance because it must be sufficient and, above all, constant. Pneumatic harvesters have a good air usage of up to 200 L/min, which means that a good flow rate is needed, especially when more than one is used at the same time.

6.1. Types

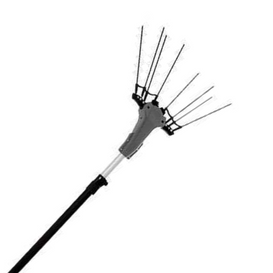

Pneumatic harvesters are generally classified according to the type of motion: vertical and horizontal. The features are the same as for electric harvesters, except that in this case a higher rpm rate will be achieved.

For these harvesters as well, there are different rakes with resin or carbon fibre prongs, but the main advantage is still the pole tube, which can also be selected either in lightweight carbon fibre, extendable or fixed type in different sizes.

7. Shakers

The manually operated shaker, unlike the harvester, is a tool that acts directly on the branch and not on the fronds. Its purpose is in fact to cause the olives to fall off by vibration and shaking at the base of the branch. It is used for late harvest or for certain varieties of olives that are easier to detach.

- Internal combustion engine

- Ergonomic gas control

- Handle

- Transmission (damped to minimize vibration shocks)

- pole(aluminium or carbon fibre, specific and reinforced)

- Hook with rollers (made of reinforced rubber material, this is the part that hooks onto the branch for shaking)

7.1. Types

These shakers are equipped with a professional-quality internal combustion engine with a good amount of power and displacement to be able to effectively drive the shaking movement given by the transmission. The transmission is solid and specific for this type of use; it is dampened between the pole and the engine to minimise vibrations passed on to the operator.

In fixed pole models, compared to backpack models, the engine is close to the operator, but they have the benefit of having a higher vibrating force. They can therefore involve thicker and more widely spaced branches, but are more suitable for use on short plants.

The internal combustion engine is placed in the backpack and is therefore behind the operator, making it less inconvenient and the throttle control more practical. The first part of the transmission is whip-drive and the vibrating force is lower compared to fixed-pole models; this makes the backpack shaker more suitable for working on single and taller branches.

Similar to petrol-powered shakers, this type of shaker also features a multifunctional design, complete with a brush cutter pole.

8. Brands

If you are looking for a reliable and high-performance harvester or shaker for professional and intensive use, you can choose from the following brands, regardless of the type of power supply:

-

Campagnola harvester -

Castellari harvester -

Volpi harvester -

Zanon harvester

If, on the other hand, you need a machine for limited, hobby use, the brands to consider are:

Lisam harvester -

Geotech harvester

Olix harvester -

Sbaraglia harvester