A comprehensive guide to purchasing the best agricultural subsoiler, with all its features and types.

The Guide to Choosing the Agricultural Subsoilers,

Comprehensive and Edited by Real Tractor Agricultural Machinery Experts

CONTENTS

1. Introduction

Agricultural subsoliers are cultivators, i.e. tools able to break the soil without turning it over or stirring it up. This preserves the soil profile as it cuts vertically and raises the surface, without drastically compromising the working surface.

The main application of the implement is tilling around 50-60 cm (but can go up to 1 m, however) to loosen soils with very hard crusts. The subsoiler, in fact, can replace the plough to break down more compact layers of soil: its use may be necessary after periods of extreme drought in which the soil is dried out and hardened by water shortages and extreme heat. It is often combined with a roller (also double) placed at the rear to maintain the necessary depth and optimise soil levelling.

The subsoiler is therefore the ideal tool for restoring the fruitfulness of unstructured and deeply compacted soils:

- preserves the organic substance through minimal alteration of soil layers (unlike the plough, which completely overturns the layer);

- restores water and air circulation within the soil, reducing the intensity of surface stagnation and, at the same time, ensures the retention of water supplies.

2. The main components of the agricultural subsoiler

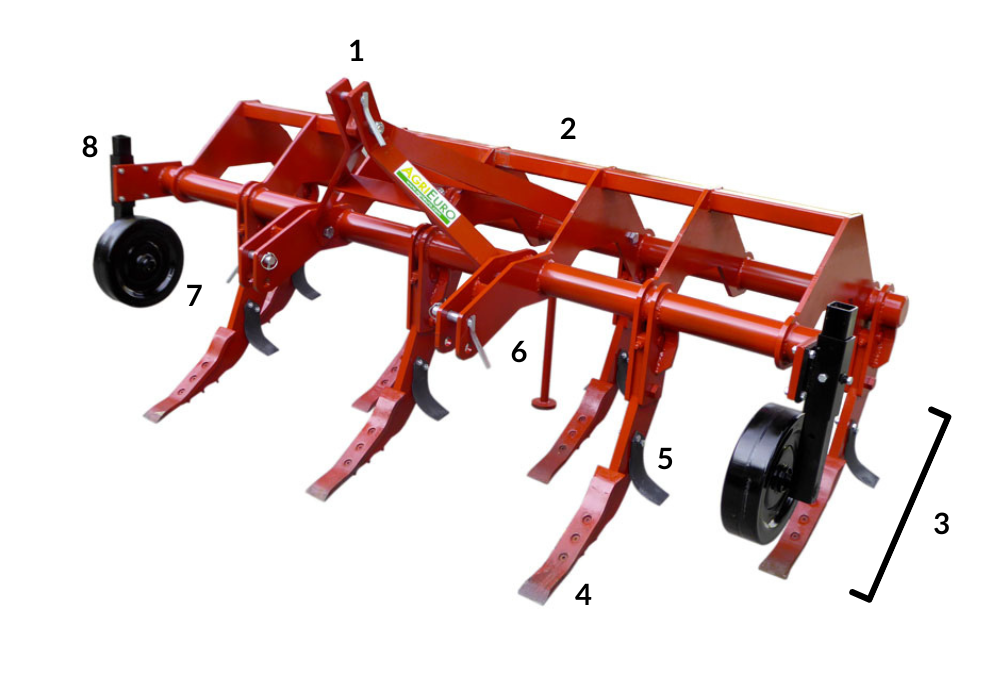

The main components that distinguish agricultural subsoilers are the frame, the three-point hitch, the depth regulator and the operating elements (tines), whose number can vary from 1 to 13.

- 3-Point hitch.

- Frame (rigid and sturdy)

- Tines (working element consisting of a structure to which the tip and lugs are attached)

- Tip (reversible)

- Lug (single or double, graduated, to break clods)

- Support for storage

- Wheels

- Depth regulator

3. Soil processing: scarifying or subsoiling

The subsoiler, or ripper, is a trailed attachment that cuts into the soil via the thrust of the hoist and the tractor’s drive. It cuts vertically, so it does not turn (ploughing) nor stir up (rotary tilling) the soil: this results in clod crumbling and the tillage looks different depending on the distance between the tines and the depth.

Ploughing

Tilling

Ripping

The subsoiler tends to do preliminary work as a replacement for ploughing because it produces minimal soil disturbance, is faster and is suitable for stony, clayey and crusty soils (with mineral deposits such as salts, limestone and gypsum, typical of hot arid regions). Furthermore, scarification can be:

- complementary: before ploughing to favour drainage and aeration of heavy soils, followed by surface ploughing. This avoids the tilling sole build-up (a compacted layer of soil created when working at the same depth all the time) whereby the organic matter is buried further to the surface;

- simultaneous with ploughing with subsoiler ploughs;

- consecutive: after ploughing with shallower depth to improve aeration and promote water penetration.

Additionally, it can be used for soil preparation, both for grass crops (cereals, seed or grazing crops), with a depth of no more than 50-60 cm, as well as for tree crops (orchards and vineyards) with a depth of up to 1 metre.

Subsoiling comes with the downside of not allowing weeds and organic fertilisers to be buried, but this is certainly outweighed by the many advantages:

- working speed (it saves time and effort, at equal depths compared to the plough, as it requires less driving force given the type of operation on the soil);

- increased space for the plant’s root growth;

- improved drainage capacity;

- improved permeability and aeration of the soil;

- absence of a processing sole.

4. Types

The various types of subsoilers differ in size, number and inclination of tines. There are subsoilers, usually with one, two or three tines, which are used to drain clay soils with a risk of water stagnation. On the other hand, those with more than three tines are used for tilling, i.e. to eliminate water stagnation.

Drainage subsoiler

Tillage subsoiler

A potential distinction can be made between fixed machines (with a safety device) or hydropneumatic machines (with a no-stop device that allows the tines to absorb shocks and stresses to reduce or eliminate damage to the frame structure).

Another difference is also in the depth adjustment, which can be achieved through the use of wheels at the front (rubberised, iron or steel) or with rollers, or crushers, which also allow the soil to be loosened and larger clods to be broken apart.

Iron wheel

Rear roller