The Complete Guide to help you choose the Best Air Compressor by the Real Experts of Workshop Equipment.

The air compressor is an equipment with a considerable range of applications, from hobby to heavy-duty use. There are different types, each characterised by technologies and features that suit every user need.

This guide aims to examine the differences between the various types of air compressors in order to get a better understanding of both their operation and the use for which each machine is built and finally to be able to choose the model that best suits your needs.

What exactly is an air compressor?

The operation of an air compressor consists of increasing air pressure by harnessing mechanical energy (compression), which is then converted into potential (or pressure) energy.

Mechanical energy can be driven in different ways, for example by a 2/4-stroke engine or, as is the case with the most popular models, by an electric motor.

This purchasing guide will discuss electric air compressors and focus on the main features and the various differences between the existing models.

CONTENTS

1. Pressure, air flow and runtime

Before purchasing an electric air compressor, it is necessary to carefully consider a number of fundamental technical aspects:

- AIRPRESSURE: AIR PRESSURE: indicated in bar, this is the pressure at which the air compressor works. Models with a maximum pressure of 8 to 11 bar are currently available on the market;

- AIR FLOW: is the amount of air produced by the compressor; it is measured in litres per minute (L/min) and is a very important value as it is one of the pointers to the “power” of the machine. In fact, for example, the greater the indicated value (L/min), the greater the power of the air jet (e.g. an air compressor with a flow rate of 100 L/min is more powerful than a model with a flow rate of 50 L/min).

There are significant differences depending on the air flow rate, which will be discussed later on; this figure should be taken into account depending on the use to be made of the machine.

The air flow is determined by several factors, such as the type and power of the pumping unit, the type and power of the motor and the size of the tank. These data therefore also strongly affect the runtime of an air compressor with tank; - RUNTIME, i.e. the time that passes before the motor has to start up again in order to compress the air back into the operating pressure range. The latter is measured by a special system, called a pressure switch, which keeps the output pressure within the set values. To achieve this, there are various technologies and devices, about which we will find out more later.

Nuair GVM/50

ABAC A49B 270 CT5.5

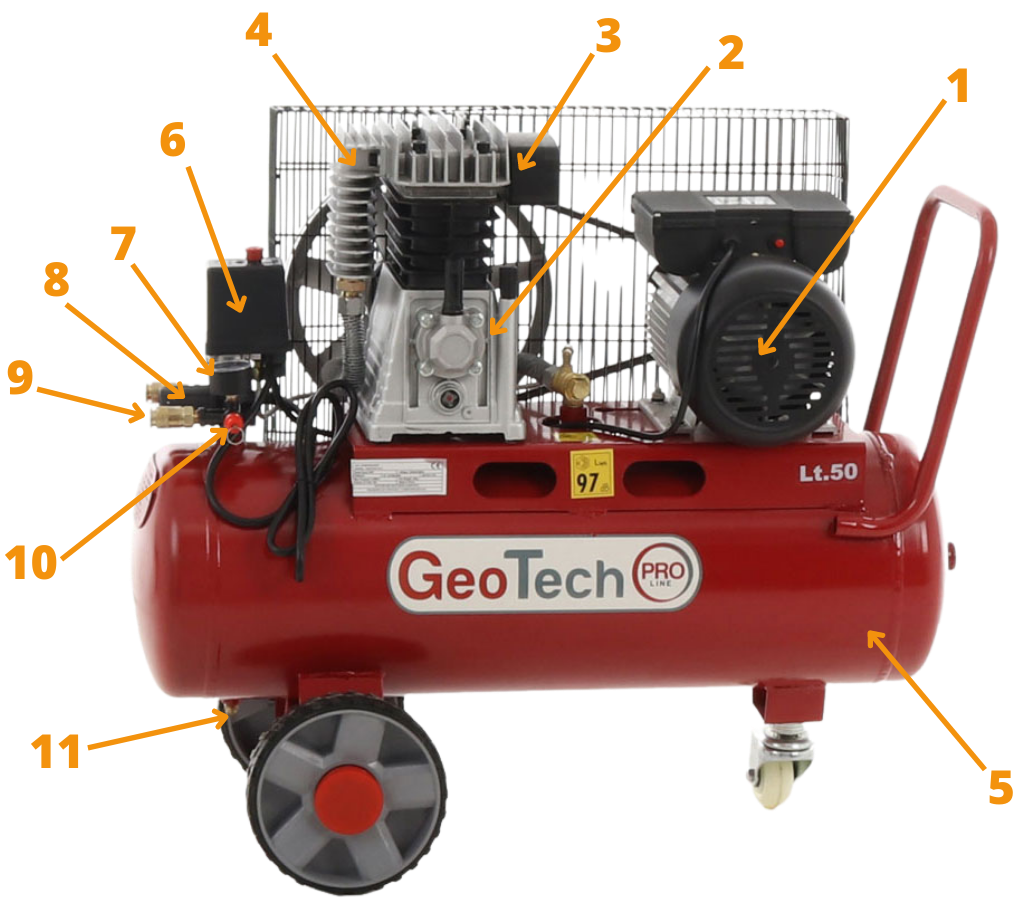

2. Components of an air compressor

| 1 | The motor | It can come with different powers and speeds depending on the type |

| 2 | Pumping unit | It may be fitted with one or more single or twin-stage pistons |

| 3 | Air filter | It is important to keep it clean at all times |

| 4 | Cooling manifold | Limits condensation production. It is only present in the best pumping units |

| 5 | Fuel tank | It can be of different litres. Proves essential to keep an air supply |

| 6 | Pressure switch | It controls the operation of the air compressor. It switches the motor on and off at factory-set pressure intervals |

| 7 | Pressure gauge | It displays operating pressure and cylinder pressure |

| 8 | Pressure regulator | Useful to set the required working pressure value |

| 9 | Air outlet joint | It can be with quick coupling or bayonet fitting. It is the air connection point |

| 10 | Safety valve | It activates in the event of pressure switch malfunction or loss of calibration, and discharges the air |

| 11 | Condensate drain valve | It is essential to activate it in order to eliminate the water that settles in the tank and mixes with the outlet air, causing damage |

3. Main components: Tank, pumping unit and motor

The main elements that characterise a classic air compressor and make a major difference between one model and another are:

- Fuel tank

- Pumping unit

- The motor

3.1. Fuel tank

The function of the tank is to contain the compressed air produced by the machine. The larger the tanks size, the greater the air supply available (always taking into account the pressure delivered by the pumping unit, which affects its capacity in percentage).

To provide a clarifying example, a 25-litre cylinder charged at 8 bar, offers a greater air reserve if charged at 10 bar.

Compact air compressor

without tank

Vertical air compressor

with tank

Air compressor with

270 L tank

Generally speaking, for a purely hobby/domestic use, the right capacity is between 4 and 50 L, whereas for a more heavy-duty, professional use, an air compressor with tank can reach far greater capacities (even 500 L).

Below, there is an indicative table of consumption according to various uses that will make it easier to understand.

3.2. Pumping unit

The pumping unit is the organ that determines the filling of the tank and constitutes the most important component of an electric air compressor because it sets pressure and air production capacity (L\min). There are different types available and they can feature different transmission systems to the motor.

This is a key element of the air compressor in terms of quality, performance and efficiency of the machine.

3.3. The motor

The motor has the function of feeding the pumping unit and also determines the filling speed of the machine, i.e. the time it takes for the tank to be completely full. It must be properly sized according to the use to be made of it. Typically, when speaking about models for hobby use, this refers to air compressors with motors of around 2 Hp, while more heavy-duty models range from 3 Hp upwards.

Electric motors generally feature a working cycle that can be divided between a 60% of working time and a 40% of resting time. However, this ratio is influenced by several factors, like the type of operation performed by the machine, the operating conditions and its efficiency.

Electric motors specifically, can be divided in 4 categories listed below depending on their design:

- S1 – Continuous Duty, i.e. the motor can continuously run with a constant load;

- S2 – Short Time Duty, i.e. the motor can run alternating between work and rest periods;

- S3 – Periodic Duty, i.e. there is a sequence of load and rest periods;

- S4 – Intermittent Periodic Duty with Starting, i.e. there is a periodic succession between starting periods and resting periods from the energy source.

Leaving aside these technical specifications, it is always a good idea to preemptively make sure of the different aspects and characteristics of the motor in order to use it in a targeted and appropriate way for the required operations.

But how can one properly choose between the various types of electric motor?

The choice of the motor type can vary according to its intended use. The main types of motor to choose from are:

- Alternating current motors – AC

- Direct current motors – DC

- Brushless Motors

The first ones are the ideal choice for who’s looking for a motor able to run at a fixed or variable speed.

The latter, on the other hand, are ideal for operations where it is necessary to adjust speed and achieve smooth movements even at maximum speed.

Finally, brushless motors, also known as “brushless”, are DC electric motors, whose main difference from “brush” motors is that they don’t need any sliding electrical contacts on the rotor shaft to run. This implies less mechanical resistance, and avoids the possibility of sparks.

4. Main types

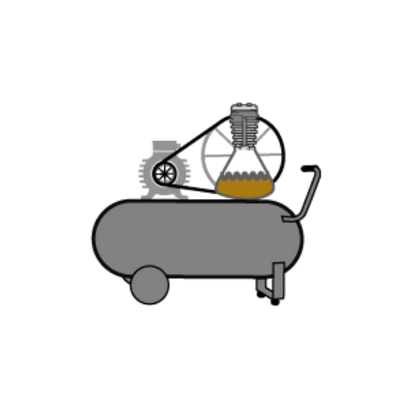

4.1. Coaxial

Coaxial air compressors belong to that air compressors class with direct transmission to the motor via the same shaft, which results in a higher (non-demultiplied) number of revolutions.

Being much more affordable, lightweight and easy to use, this category of air compressors is the most suitable for users needing a machine suitable for hobby and domestic use to carry our small to medium tasks.

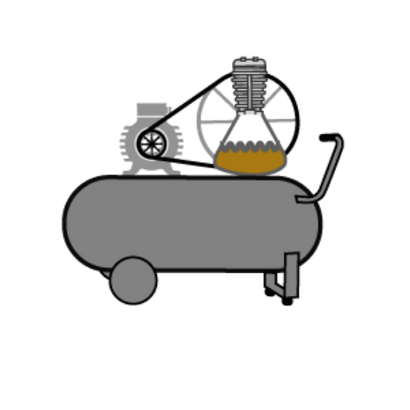

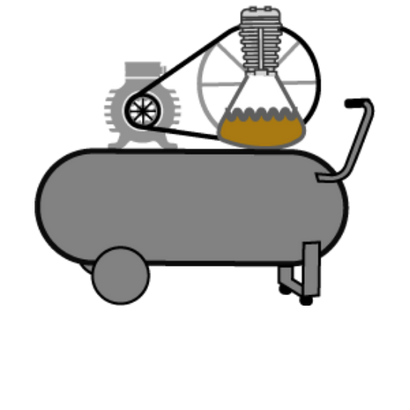

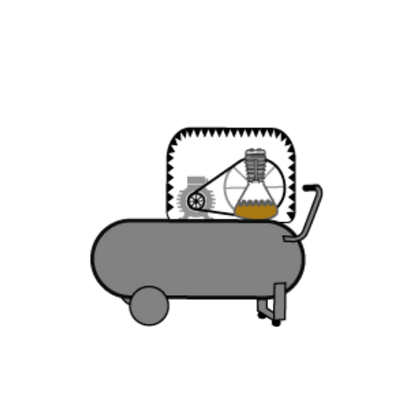

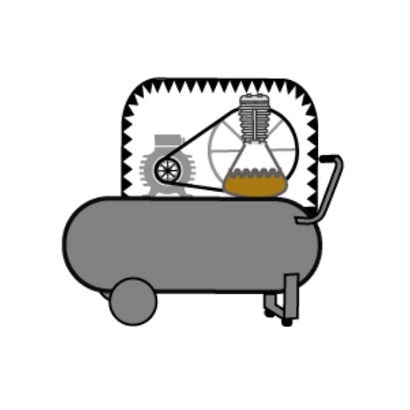

4.2. Belt-driven

If coaxial air compressors are best suited for hobby and limited use, belt-driven air compressors represent a more heavy-duty type that suits the most demanding user.

These models mount a motor connected to the pumping unit via a belt, which allows the pump’s revolutions to be reduced, resulting in a much longer working time compared to a coaxial system.

5. Fuel:

- Single-phase 230V

- Three-phase (400 V)

- Battery-powered air compressors

The most common power supply is undoubtedly the single-phase 230 V mains supply; it is always a good idea to check that the cross-section of the power cable (extension cord) is the right one, especially in those cases where the motor power is higher.

On the other hand, the three-phase 400 V power supply is typical of heavy-duty models with higher than standard power; it is ideally suited for business and workshop use.

Goodyear GY 250D single-phase air compressor

ABAC S A39B 200 CT3 three-phase belt-driven air compressor

Finally, worth mentioning are the latest battery-powered models, which prove very convenient in terms of portability and are suitable for more limited, hobby use.

RYOBI R18AC-0 portable battery-powered air compressor

Blackstone SBC 05-07 battery-powered air compressor

6. Pumping unit

The pumping units can be single-cylinder or twin-cylinder and these in turn can be:

- Single-stage

- Twin-stage

Fiac AB 100/360 M single-stage

air compressor

ABAC ABAC A49B 200 CM3 Air Compressor

Twin-stage

6.1. Single-stage

Single-stage pumps require onlyone compression stage: the air is compressed directly into the tank and this results in a lower flow rate, which can be as much as 35% lower than the reported figure for air intake flow.

6.2. Twin-stage

In twin-stage pumping units, the air is first compressed, cooled and then, in a second stage, compressed again: this allows for a much higher efficiency which translates into a higher percentage of air output than air intake (-20% compared to the reported figure).

Following on this, it is safe to assume that twin-stage pumping units offer far better efficiency, are more sophisticated in design, boast better cooling and lower noise, and are therefore suitable for more intensive and continuous use.

7. Types of air compressors

Among the main types of air compressors there are:

- Portable

- Small\medium-sized (26-50 L)

- Medium\large-sized (50-100 L)

- Large-sized models (over 100 L)

- Silenced

- Screw

7.1. Portable

Extremely practical thanks to their high transportability and compact size, small-sized 12 V air compressors for cars are mostly hobby models (with the exception of a few higher-performance versions) and more reasonably priced than other types.

How do they work? What can they do?

These air compressors are generally very compact, portable and feature a power socket to plug into the car’s cigarette lighter.

The operation of these compressors is direct, they have no storage tank and require much longer filling times than the more advanced types.

Although they are generally not suitable for air blowing, they are still able to reach high pressures to inflate both the tyres of a motorcycle or car (generally used in emergency situations, when there are no other solutions available), and other small objects (such as, balloons, small inflatables, air mattresses…).

Immediately following the 12 V models in a higher rank are the 230 V models; these air compressors are still direct but offer a higher flow rate and, albeit to a limited extent, are also suitable for air blowing.

Black & Decker BDCINF18N-QS

Fiac F3100 air compressor

Stanley AIR KIT air compressor

Among the 230 V electric air compressors we can find models with a storage tank; the capacity of this type is limited to a few liters but they come with the great advantage of being conveniently transportable easy to store thanks to the compact size.

ABAC Silverstone OS20P air compressor

Fini SILTEK S/6 air compressor

DeWalt DPC6MRC-QST air compressor

The “direct” models feature no belts and, as a result, the pumping unit and the motor are directly connected.

Direct air compressors differ not only in power and capacity, both crucial aspects in defining product quality, but also in lubrication, which can be with oil or oil-free. The latter type benefits from being easily to transport without the risk of spilling lubricant during movement, but the downside is the greater wear and tear on the pumping unit. In any case, it is fair to say that it is possible to restore full efficiency by sourcing affordable repair kits.

Although they are generally designed for hobby use, among the more compact and portable models, there are some more compact and portable models, suitable for heavy-duty use.

7.2. Small\medium-sized models (26-50 L)

This type of air compressors fit tanks with capacities ranging from 26 to 50 L. This category includes both more cost-effective models, suitable for a domestic\hobby use and equipped with direct drive, and semi-professional models, such as the more powerful 50 L belt-driven air compressors.

Vinco KWU7502-50L air compressor

Michelin MB 50 6000 U air compressor

Hyundai KWU750-50L air compressor

7.3. Medium/large-sized models (51-100 L)

Medium/large air compressors encompass those with a capacity ranging from 50 to 100 L.

Models equipped with belt-drive are recommended for both the demanding hobby user and for a semi-professional use, especially the versions with more powerful, high-performance motors, that can also adapt even to, for example, occasional painting works.

Three-phase models, such as 100 L air compressors, also start to enter this category, and come with the benefit of a more powerful motor combined with a higher performance pumping unit.

7.4. Large-sized models (over 100 L)

This includes all large-sized air compressors with tank capacities of over 100 L; within this category some single-phase versions can still be found, but the highest performance will most certainly be achieved with the three-phase versions. In fact, these models are the best suited for workshop or small heavy-duty use, as they feature the most powerful motors combined with the highest performance pumping units, in addition to the large tank capacity.

7.5. Silenced

All low-noise models can be listed in this section; from the ultra-silent hobby models (whose noise emissions are only slightly higher than the noise of a refrigerator), which are also suitable for carrying out do small jobs around the house without being noisy, to the more heavy-duty semi-silent models intende, for example, for a workshop with open spaces.

7.6. Screw

Electric screw air compressors represent the cutting edge of power and technology. They come with a higher mechanical efficiency and feature a more essential structure compared to the classic pumping units models mentioned above. These are often employed in workshops and laboratories for continuous use and are equipped with extremely useful accessories such as heavy-duty specific air dryers (for industrial quality requirements in air treatment).

Fiac NEW SILVER 3/90 air compressor

Fiac NEW SILVER 10/300 air compressor

Fiac NEW SILVER 10 air compressor

8. Uses

| USES | CONSUMPTION |

| Inflating bicycle tyres | LOW |

| Car\motorcycle tyres inflation | MEDIUM/LOW |

| Oiling | MEDIUM |

| Twin hammer air impact wrench | MEDIUM/HIGH |

| Sandblaster gun | HIGH |

| Painting\airbrush gun | HIGH |

| Hammer drill | HIGH |

| Pneumatic grinder | HIGH |

9. Brands

As far as brands are concerned, if you are looking for a high-performing and reliable electric air compressor, these manufacturers may be the right choice for you as their range of products is suitable for even the most experienced and professional users:

- ABAC,

- FIAC,

- NUAIR Group owner of the FINI brand.

If, on the other hand, you are not a professional but still need a top-quality electric air compressor for purely hobby use, you can check out the models manufactured by GeoTech, GeoTech Pro and BlackStone.

GeoTech S-AC50-8-10×2 air compressor

GeoTech Pro BACP50-8-2 air compressor

Blackstone B-lLBC 100-30 air compressor