A comprehensive guide to purchasing the best outdoor or built-in oven for pizza and cooking, with all available versions and their functions.

The Guide for Orienteering Your Choice on the Best Outdoor or Built-in Ovens Completed and Edited by Real Experts in Outdoor Cooking.

Among the most popular and desired items for one’s garden, especially during the summer season, are definitely outdoor ovens. With these you can conveniently prepare and organize outdoor dinners with friends and family.

CONTENTS

1. The categories

There are now many types of ovens available, which can vary from each other in terms of power supply, but also in terms of cooking method, so you can find:

- Wood-fired ovens;

- Gas ovens;

- Wood Pellet ovens;

- Electric ovens.

Wood-fired ovens are the most traditional category, the largest in size, and also the most expensive given the many possible methods of preparation.

Gas ovens, which are particularly popular with those who do not have large spaces, due to their small and compact size, allowing them to be placed in tight spaces.

Finally, wood pellet and electric ovens, which are more environmentally friendly alternatives to traditional wood-fired ovens, are also compact in size and have a low cost.

Let’s try to summarize and compare advantages, disadvantages and main features of all categories.

| Price | Number of cooking chambers | For indoor use | For outdoor use | |

| Wood-fired ovens |  |   1-2 chambers |  |  |

| Gas ovens |  |  1 chambers |  | |

| Wood Pellet ovens |  |  1 chambers |  | |

| Electric ovens |  |  1 chambers |  |

2. Wood-fired ovens

Wood-fired pizza ovens harness the combustion of wood for baking and preparing not only pizza, but also other food, bread especially. The main difference in wood-fired ovens is based on the cooking method; in fact, in addition to built-in models, which are a separate category, outdoor wood-fired ovens can have one or two cooking chambers that either use the direct or indirect cooking method.

They are divided into three different models:

- Indirect Cooking Outdoor Wood-fired ovens;

- Direct Cooking Outdoor wood-fired ovens;

- Indirect Cooking built-in wood-fired ovens.

2.1 Indirect Cooking Outdoor wood-fired ovens

Indirect Cooking Outdoor wood-fired ovens have two separate chambers, one called the combustion chamber, which is precisely where wood burning takes place, and a cooking chamber, where the food is then cooked.

The method by which heat is distributed from the combustion chamber to the cooking chamber varies from the technology and innovation of the oven.

In fact, in some models there is a cavity extending from the combustion chamber and surrounding the cooking chamber, these however are spaced by a small gap that prevents the flames from directly lapping the chamber, preventing excessive wall heat and reduced longevity of the steel plate between the two chambers.

In others models, there is rock wool on the sides and above the cooking chamber, a specific material that maintains a constant temperature, therefore avoiding excessive heating and increased wood consumption.

In an indirect wood-fired oven, combustion takes place in a separate chamber from where the food is cooked, isolating the two compartments from each other, and more importantly, avoiding having to cook the food in close contact with the wood and embers: this ensures first of all greater hygiene during preparations, and secondly, a much easier and faster chamber cleanup.

The very possibility of easy cleanup, also combined with the larger size and the ability to cook larger quantities of food at the same time, make indirect cooking ovens the most suitable for professional use as well.

The heat released is directly distributed to the cooking chamber, this is positioned right above where the wood combustion takes place. This method creates optimal internal air circulation to such an extent that a ventilation system is not often necessary. This method, creates optimal internal air circulation to such an extent that a ventilation system is not often necessary.

They can reach high temperatures in a very short time and keep them constant, consequently speeding up preparation time compared to traditional ovens.

The combustion chamber and the cooking chamber are usually separated by a double layer, consisting of a steel top, thick refractory bricks positioned under a refractory slab; these special materials absorb the heat from the wood combustion and redistribute it equally throughout the cooking chamber.

Some models have small refractory slabs in the walls as well, for a more even cooking and heat distribution, especially for models with multiple cooking surfaces.

This composition allows optimal heat distribution over the entire surface and prevents the formation of areas with different temperatures between them.

Let’s summarize the main advantages and disadvantages of indirect cooking wood-fired ovens.

| Advantages | Disadvantages |

| Cooking food away from embers and smoke | They take up a lot of space |

| Larger dimensions of the cooking chamber | The most expensive category |

| Also suitable for professional use | |

| Multiple cooking surfaces available | |

| Easy cleanup |

2.2 Direct Cooking Outdoor wood-fired ovens

Direct Cooking Outdoor wood-fired ovens allow reduced firing and preheating times compared to indirect cooking.

In these models we don’t find two separate cooking chambers, but a single one where the food is cooked in direct contact with the embers and smoke, which is expelled from the chimney.

This brings out the flavors in the food, with the cooking process being more complex than indirect cooking, precisely because the food is in close contact with the flames, making temperature regulation more complicated.

The cooking chamber is vault-shaped for optimal heat distribution and heating efficiency, while the cooking surface is made of refractory material, certified for food use.

On the side is then the inner brazier, where the wood is to be placed and from where the flames are released.

Let’s summarize the main advantages and disadvantages of wood-fired ovens with direct cooking.

| Advantages | Disadvantages |

| Almost always small sized | Difficult temperature regulation |

| Food in direct contact with wood and embers | |

| More complex chamber cleanup |

2.3 Indirect Cooking built-in wood-fired ovens

Built-in wood-fired ovens are indirect cooking ovens; they are placed inside special recesses in walls or suitable spaces, in both indoor and outdoor kitchens. Therefore, they can play the role of both classic outdoor wood-fired ovens as well as traditional domestic ones. The cooking method is the same as that of wood-fired ovens with double cooking chambers, so they use the heat given off by the wood combustion in the specific chamber to cook food placed inside a second, separate chamber.

The advantages in choosing this category of wood-fired ovens for indoor kitchens as well are:

- Saving electricity: The use of wood avoids excessive electricity consumption;

- Possibility of multiple firings: With this kind of oven it’s possible to cook many great meals without having to compromise on any dishes;

- Aesthetic factor: Built-in ovens, thanks to their modern and functional design, fit perfectly into most kitchens.

Let’s summarize the main advantages and disadvantages of built-in wood-fired ovens.

| Advantages | Disadvantages |

| Cooking food in separate chambers | Large size |

| Excellent aesthetic presence | High price |

| Can be used both indoors and outdoors |

3. Gas ovens

Gas pizza ovens, due to their compact size and light weight, can be placed in smaller and more inconvenient places than wood-fired ovens.

Of course, the dishes will not have the same aroma as those made with wood-fired models, and the time they take to reach the ideal temperature will be longer, but for those looking for a good compromise between flavor and convenience, these models are ideal.

In gas ovens, cooking food is done precisely though burners which generate constant high heat that can be easily adjusted by using the external knob.

Therefore, there is no need to worry about handling wood, smoke, ignition and flame regulation. In addition to its compact size, another appreciated advantage of this category is its ease of use.

The oven once connected to the gas cylinder is ready to be used, all you need to do is turn on the nozzles using the power knob and activate the piezoelectric, at this point once the desired temperature is reached you can start cooking food.

Let’s summarize the main advantages and disadvantages of gas ovens.

| Advantages | Disadvantages |

| Small size | Limited use |

| Easy temperature control | It takes a long time to reach the temperature |

| Doesn’t generate smoke | |

| There is no need to worry about the flame |

3.1 Hybrid gas ovens

For those who don’t want to give up wood-fired cooking, but also don’t wish to renounce on the practicality of gas models, it’s possible to turn to an extremely functional category: Hybrid ovens

These are ovens that can use both wood and gas cooking methods.

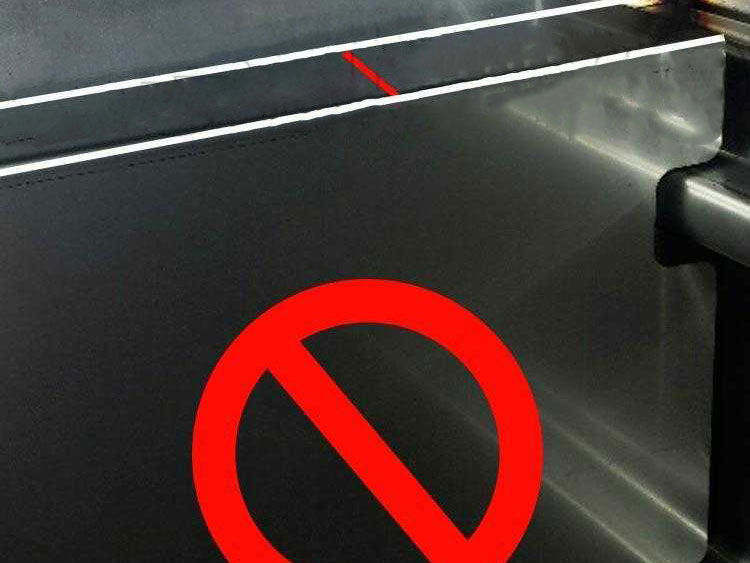

Switching to different uses is very simple, in most models all you need to do is to raise or lower an internal steel bulkhead and use a special conversion kit that is included with the product.

They combine the features of both categories in one model: there is a side brazier in the cooking chamber for wood-fired cooking

While the various nozzles for gas cooking are placed under the refractory surface.

This hybrid category allows you to choose between barbecuing or faster gas cooking in a quick and timely manner depending on the time you have for various preparations.

| Advantages | Disadvantages |

| They allow both wood and gas cooking | Fairly high price |

| Simple switching between the two cooking methods |

4. Wood Pellet ovens

Wood pellet ovens harness the combustion of this particular organic material, which can be produced from pruning residues and other plant waste. If you want to learn about all aspects of this material, here is our dedicated guide.

More environmentally friendly than gas models and, as a result in terms of aroma, are the most similar to wood-fired ovens. In fact, flame and radiation are equal and allow cooking in direct contact with the fire.

The dimensions, on the other hand, are small and compact, like gas-fired ovens, allowing those who want to use them to do so on tables or small dedicated spaces.

| Advantages | Disadvantages |

| Small size | They require a constant amount of pellets |

| Affordable | Limited use |

5. Electric ovens

A hobbyist compromise for those who do not want to give up making their own pizza, bread, or pastries while not having ample outdoor space.

Electric-powered ovens are ideal for urban settings and to get rid of the problems of wood and gas.

They are simple and convenient to use, just plug them into your household power supply and turn them on by rotating the knob to get them ready for use.

Let’s summarize the main advantages and disadvantages of electric ovens.

| Advantages | Disadvantages |

| Small size | Limited use |

| Affordable | They have to be connected to the electrical outlet |

| They don’t generate smoke |

6. The ventilation system

Ventilation within the ovens plays an important role in properly cooking various dishes.

Ovens can be:

- Ventilated;

- Ventilated with ducted ventilation;

- Ventless.

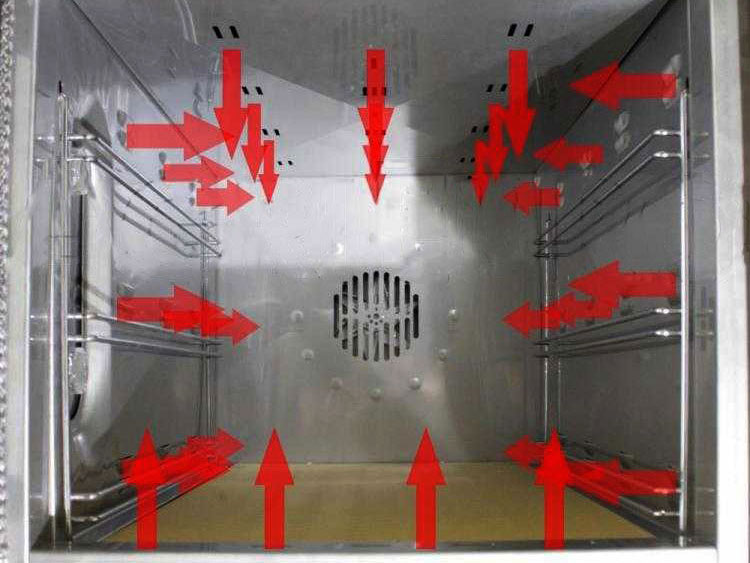

- The vast majority of indirect cooking ovens, mount a fan motor or fan at the bottom of the cooking chamber, with a direct emission of air from the back of the chamber. On the bottom, in fact, a special fan is clearly visible, which ensures the proper distribution of air while cooking; this is particularly suitable for baking cakes.

- While the ducted ventilation system allows an even heat distribution thanks to a gap that surrounds the cooking chamber for its entire depth, so air is distributed not only by the fan on the bottom but also from all its sides through special slots.

With this system, ventilation also passes under the refractory slab making the distribution even and supplying an additional air outlet. This allows the heat to distribute to the front of the oven as well, creating a kind of barrier that prevents it from being released when the door is opened.

In addition, the cooking chamber also gains depth, given that in the case of ovens that mount the fan motor this is covered by a steel panel that occupies up to 5 cm of space, thus reducing the actual chamber space.

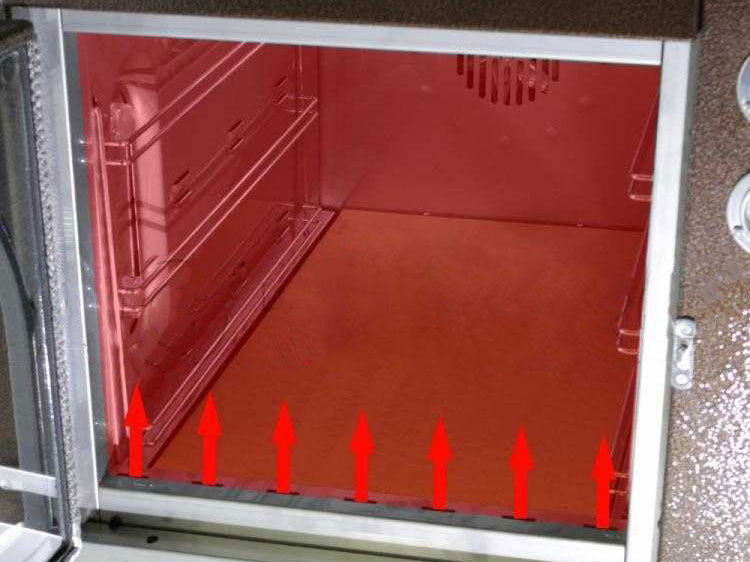

- Lastly, ventless ovens, which don’t have a fan at the bottom or a ventilation system distributed around the sides of the chamber and therefore only allow static cooking.

7. Materials

The materials that can coat the exterior surfaces and finishes of ovens are different, each with different features.

The outer structure is often made of steel, given this material’s excellent resistance to heat and its great durability. The latest models in particular feature an exterior made of electro-galvanized steel, a material that is particularly resistant to rust.

Another commonly used material is cement, or rather, a refractory cement mix, which is extremely solid and durable and used for larger models of outdoor wood-fired ovens.

Also widely used for exterior oven structures is stainless steel, which is long-lasting and makes the oven extremely weatherproof.

7.1 The material of the doors

As for the doors, they too can be made of different materials such as: enameled steel, cast iron, and stainless steel.

- The enameled steel door is the cheapest of the three; it still has excellent thermal efficiency;

- The cast iron door is the heaviest, retains heat excellently, and is not subject to deformation caused by high temperatures;

- While the stainless steel door is the most resistant of all to weather and corrosion.

8. The cooking surfaces

The cooking surfaces are the levels on which food can be cooked; there are one, two or three depending on the types and sizes of ovens.

The single cooking surface is found on all direct cooking ovens, gas ovens, wood pellet ovens, and electric ovens.

It consists of only the refractory stone surface, for food use, where the pizza or other food is set. They are used in smaller cooking chambers for private and more limited areas.

Ovens with two cooking surfaces represent a middle ground between the more hobbyist one-tier oven and the more professional three-tier kind.

They consist of a refractory top at the base and a steel support grid, where pots and pans can also be placed.

With a 2-tier cooking chamber, it’s possible to cook even multiple meals together.

On professional ovens and with large cooking chambers, there are up to three cooking surfaces

These have in addition to the refractory slab, two removable steel grids, which lie on special side bars.

The grids can be either used together or removed and positioned according to one’s needs and the different cooking to be done.