Read the purchasing guide to the best hot water pressure washer, with all their main features, models and functions.

The Guide to Choosing the Best Hot Water Pressure Washer, Comprehensive and Curated by Real Washing and Cleaning Experts.

CONTENTS

1. Introduction

Pressure washers are the most effective machines used for cleaning outdoor areas, cars, equipment and outdoor furniture. These machines employ a high-pressure water jet to remove dirt or debris.

There are different models of pressure washers:

- Cold water pressure washers;

- Hot water pressure washers;

- Petrol-engine pressure washers;

- Tractor-mounted pressure washers.

This guide will help you choose the best hot water pressure washers.

However, if you want to know all the specifications of cold water pressure washers, here is our guide dedicated to those models.

The hot-water pressure washer offers the great advantage, unlike the other types, of being able to degrease and clean even surfaces soiled with oil or grease, thanks to the high temperatures it reaches.

The combined action of the high temperature water and high pressure, therefore, allows optimal cleaning of surfaces and also requires less detergent.

The efficiency of using hot water, compared to cold water, is considerably higher as the heat melts the dirt, and in addition, acting on the surface also facilitates its drying.

Due to these characteristics, this category of pressure washers is widely used in professional, industrial, construction and agricultural sectors.

The highest performance is provided by single-phase and three-phase models, which are suitable for intensive and continuous use, with the highest-end models reaching up to 2800 RPM for 4 kW of power.

The most important properties to evaluate in a pressure washer, apart from the drive, as just mentioned, are:

- Power;

- Flow rate;

- Pressure.

Let us now try to summarise these main aspects of hot water washers according to their various levels of use, and then analyse them specifically one by one.

| Drive | Engine | Power | Flow rate | Pressure | |

| Low level | Single-phase | Induction | 1.5 – 2.4 kW | 7 – 7.9 L/min. | 130 – 149 Bars |

| Medium level | Single-phase | Induction | 2 – 3 kW | 8 – 11 L/min. | 130 – 160 Bars |

| High level | Three-phase | Induction | 3 – 4 kW | 11 – 13 L/min. | 160 – fino oltre 200 Bars |

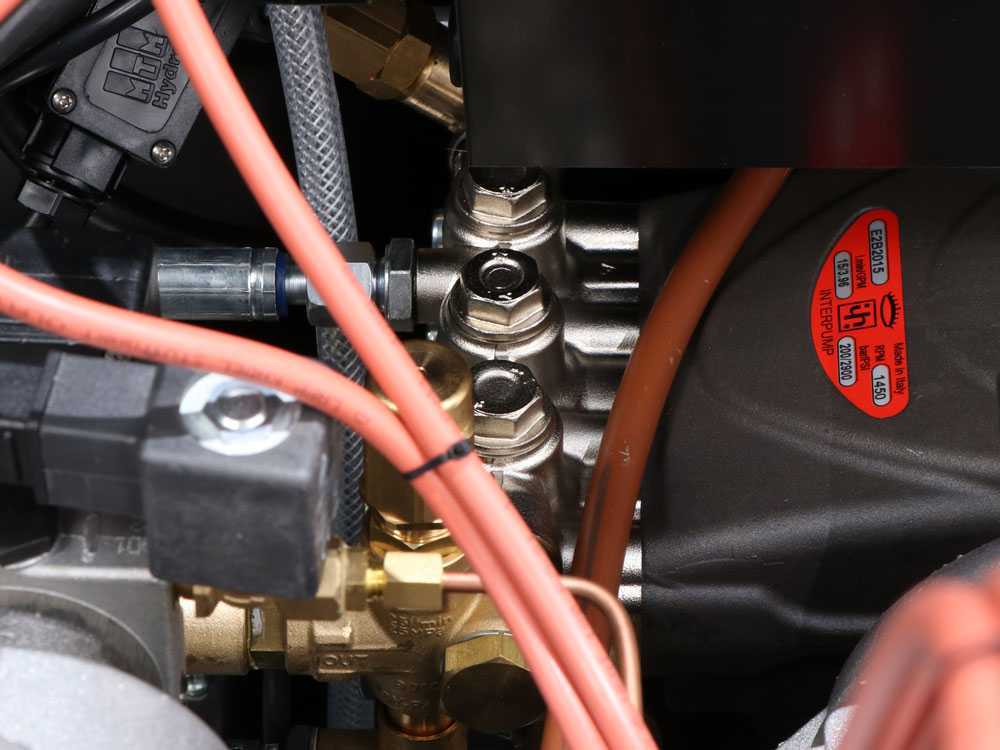

2. The internal boiler

Before analysing the main features of pressure washers, let us discuss the real and substantial difference that sets hot water washers apart from all the other models: The integrated boiler.

The boiler is the part that provides the hot water; it is integrated in the structure of the machine, under the protective casing, near the electric motor and is directly connected to the diesel tank, which feeds it.

It heats water to very high temperatures, which can reach up to 150° in the most professional models.

La sua presenza però aumenta il peso e l’ingombro della macchina, riducendone la maneggevolezza.

Di conseguenza le dimensioni delle idropulitrici ad acqua calda sono tra le più grandi della categoria.

IMPORTANT:Hot water should never be used simultaneously with chemical detergent.

The combined use of these two elements in fact causes fouling of pipes and the internal coil, often irreparably damaging the entire boiler.

Thanks to the controls, you can easily choose between hot and cold water and adjust its temperature to your liking.

In the picture we can see an example of a generic hot water pressure washer control panel where:

- The first display indicates the pressure Bar level;

- The second knob is used to choose between cold and hot water use;

- The last knob, is the one that allows you to choose water temperature.

3. Drive

Among electric hot water pressure washers, the main difference in power supply is between single-phase 230 V and three-phase 400 V machines.

- Single-phase pressure washers have a common household power supply, so they can be conveniently connected to household sockets.

They reach medium to low power levels, and deliver water at a pressure of up to 160 Bars

They are therefore primarily used in domestic or, in the case of the more powerful models, semi-professional environments.

- Three-phase pressure washers are the most powerful and effective. They are used in the professional sector because of the great power they can achieve.

They can deliver up to 4 kW for a water pressure of over 200 Bars.

4. Power and motor

The motor power is expressed in kW, and denotes the power consumption of the various models.

Machines up to 3 kW are for normal domestic use, beyond that are for professional use.

The motors of hot water pressure washers are induction, or brushless, these motors are the quietest and since they do not have brushes they also require less maintenance.

In the higher-end models, you can also find 2- or 4-pole induction motors, which allow you to reduce the motor’s rotational speed (RPM) while still delivering the same power.

A low RPM means higher motor performance; on the contrary, the higher the RPM, the more the motor decreases in power and performance.

2-pole and 4-pole induction motors work at low speed, around 1450 RPM in the best performing cases, which means greater efficiency and durability not only of the motor but also of the pump.

In hobbyist pressure washers, on the other hand, the motors work at around 2800 RPM, with lower performance.

5. Flow rate and pressure

Flow rate and pressure are certainly among the most important parameters to consider in a pressure washer, as they express the real power and validity of the machine.

The flow rate of a pressure washer is measured in L/min. (litres per minute) or L/h. (litres per hour), and indicates the amount of water the pump can deliver.

This is a figure that is often overshadowed by the pressure, but is actually the one that best expresses the cleaning capacity of the machine.

Models with a high flow rate have a much more powerful jet.

Thus, a machine with a high flow rate will be able to create a substantial jet of water, whereas, machines with a low flow rate will create a weaker jet with less water.

| Flow rate | Litres per minute |

| Limited flow rate | Up to 6.9 L/min. |

| Low flow rate | 8 to 9 L/min. |

| Average flow rate | 10 to 11 L/min. |

| High flow rate | 13 to 15 L/min. |

| Very high flow rate | Over 15 L/min. |

Pressure, on the other hand, is expressed in Bars, and indicates the force with which water is delivered.

The higher the pressure, the more effective the cleaning will be, especially of outdoor pavements or walls.

Be careful, however, to evaluate this figure attentively, and to choose it wisely according to your needs,

excessive water pressure in fact risks damaging particularly delicate surfaces, car bodies, etc…

| Pressure | Bars |

| Limited pressure | Up to 119 Bars |

| Low pressure | 130 to 139 Bars |

| Average pressure | 150 to 159 Bars |

| High pressure | 170 to 199 Bars |

| Very high pressure | Over 200 Bars |

Therefore, the important fact to understand before choosing a pressure washer is that higher water pressure does not always mean easier and more effective cleaning, and at the same time, higher flow rates can sometimes prove useless for various cleaning tasks.

It is therefore essential to adequately analyse the intended uses for the machine, choosing a model with adequate flow rate and pressure.

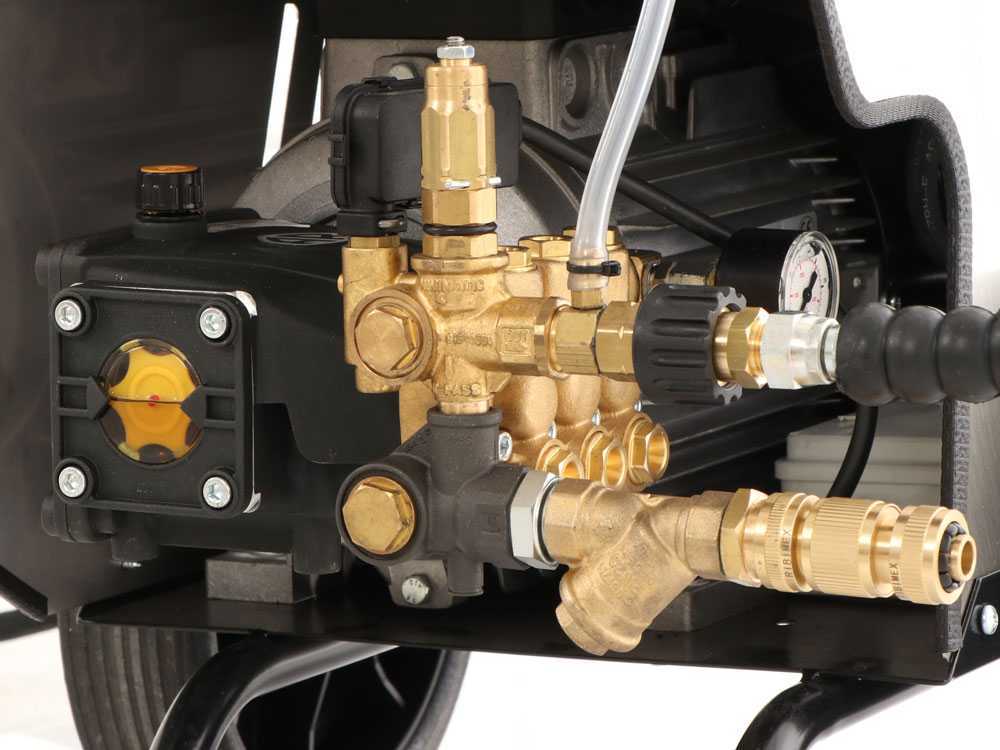

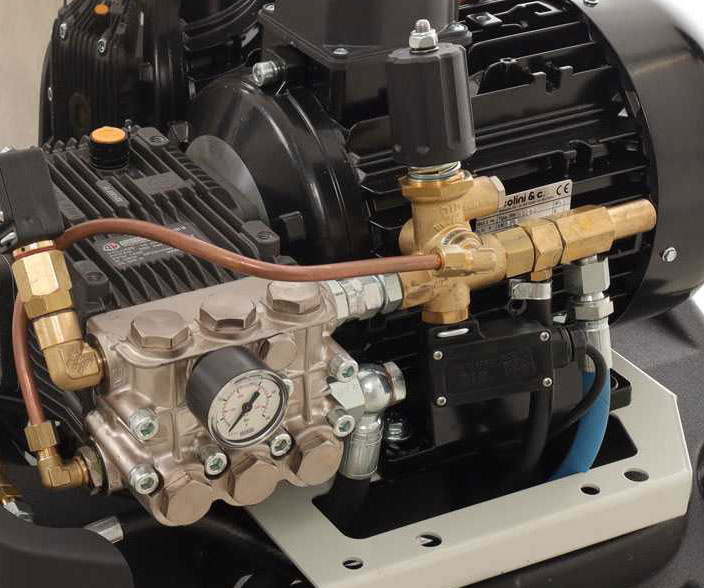

6. The type of pumps and their characteristics

The pump is a key component of a pressure washer, as it is in charge of generating high-pressure water jet.

There are two different types of pumps:

- Axial Pump: It is the most common type on pressure washers, providing good performance at a low price.

Made from less professional materials, such as aluminium, or in the higher-performance versions, steel.

The cylinder head is mounted in front of the crankshaft, where a plate oscillates and sends the pistons back and forth. - Linear Pump: A pump type that combines high performance with optimum simplicity of construction.

The pistons move like in a car, with a connecting rod system that sends them up and down, consequently the pump is mounted with the pistons perpendicular to the crankshaft.

Cylinder heads are also very important to understand the level of use of the machine:

- The aluminium cylinder head is a good trade-off between price and performance, and is usually found on axial pumps.

They are in fact fitted on hobbyist and semi-professional performance pressure washers; - The brass cylinder head, on the other hand, is the most resistant type to high pressures on the machine, as brass is among the hardest metals in nature.

They are fitted to professional-level pressure washers with the greatest performance and use; - Lastly, nickel-plated brass cylinder head makes the pump even more durable, increasing the reliability of the pressure washer to the maximum.

Finally, the pistons, which can be made of steel, ceramic steel and ceramic:

- Steel, mostly common in hobbyist and semi-professional machines due to its low price and good quality;

- Ceramic steel, a variant of ceramic-coated pistons, a suitable middle ground between ceramic and steel pistons;

- Ceramic, the highest-quality pistons, guarantee long life and great performance.

Exclusively fitted on professional machines.

7. Available accessories

When purchasing a pressure washer, it is possible to have, or purchase separately, numerous accessories that allow for extra work, other than the classic high-pressure water jet cleaning.

Among the various accessories available for hot water pressure washers include:

- Foam lance;

- Detergent tank;

- Rotating nozzle;

- Hose reel.

Among the most popular and commonly used accessories is the foaming lance, mainly used for washing cars.

Closely connected to the foaming lance is the detergent tank, which can be integrated on both the machine and the lance, and which contains the chemical detergent required.

Another popular and widely used accessory is the rotating nozzle, a lance that, thanks to this particular adapter, concentrates all the water flow on a single spot, generating a rotating jet.

Finally, the hose reel, which allows the high-pressure hose to be rolled up and stored.

8. Other functions

Additional features that can be found on pressure washers include:

- Delayed Total Stop: Denotes the non-immediate interruption of the water supply and the pressure washer.

Usually, releasing the gun causes the water and the machine to stop immediately, however, this operation, if repeated insistently at short intervals, can lead to accelerated deterioration of the pressure washer and its components.

With this function, the water continues to be supplied even a few seconds after the gun is released, allowing it to be opened and closed without completely blocking the machine; - Pressure regulator: Allows adjustment of the water jet pressure.

This is especially useful when working on surfaces that require cleaning with the jet at different pressures.