Guide on the correct maintenance of the shredder. Operations and steps to be performed to maintain the machine correctly.

A guide to the main Shredder Maintenance operations.

The garden shredder is the leading disposal solution for winter and summer pruning residues and other general waste from gardening activities.

But what maintenance does it require?

In this guide, we will carry out a comprehensive overview of its maintenance to ensure optimal results and performance throughout the season.

CONTENTS

Garden Shredder maintenance: Three phases

The maintenance phases of a garden shredder throughout the year can be divided into three main segments:

- Early season maintenance;

- Routine maintenance;

- Pre-storage operations.

We will look at all the maintenance work to be performed, the steps and tricks needed to maintain all shredder models at their best.

1. Early season maintenance

In this first chapter, we will look at start-up maintenance for the shredder, i.e. all the work to be carried out if the machine has been idle and out of use for a prolonged period of time.

At this stage, the main precautions are related to the components of the internal combustion engine, since the air filter, spark plugs, engine oil, etc. have to be checked.

For an electric model, on the other hand, maintenance is much quicker and is limited to a simple inspection and cleaning.

So let us concentrate on the most challenging case scenario, i.e. an internal combustion shredder; the maintenance to be performed can be summarised as follows:

- Refuelling;

- Engine oil change;

- Air filter check;

- Spark plug check;

- Battery connection;

- Clearing:

- Blade check;

- Belt inspection.

1.1 Refuelling

Among the first operations to be performed at the start of the season or after a long period of downtime is certainly the renewal of the fuel.

As with all machines powered by internal combustion engines that have to be reused after a long standstill period, the renewal of old fuel is essential.

Therefore, if the fuel has been left in the tank for as long as it has not been used, it must be replaced with new fuel to avoid serious damage to the engine.

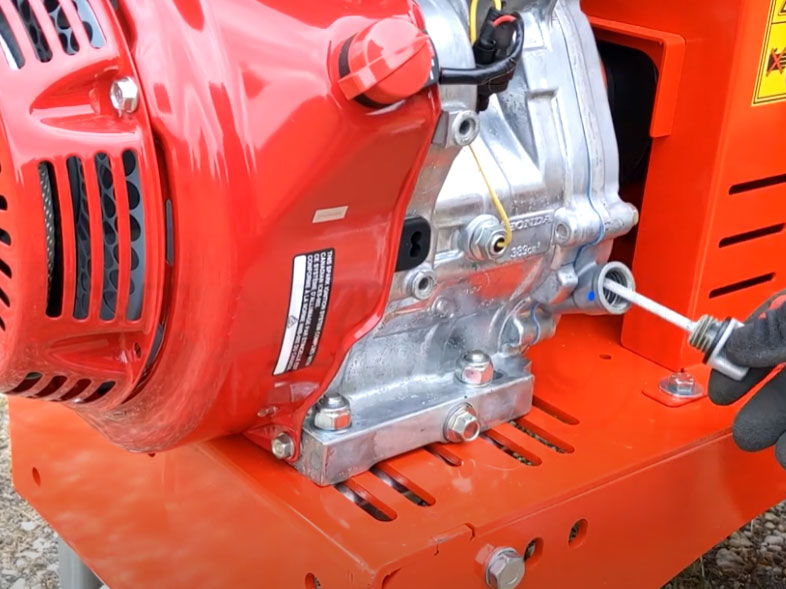

1.2 Engine oil change

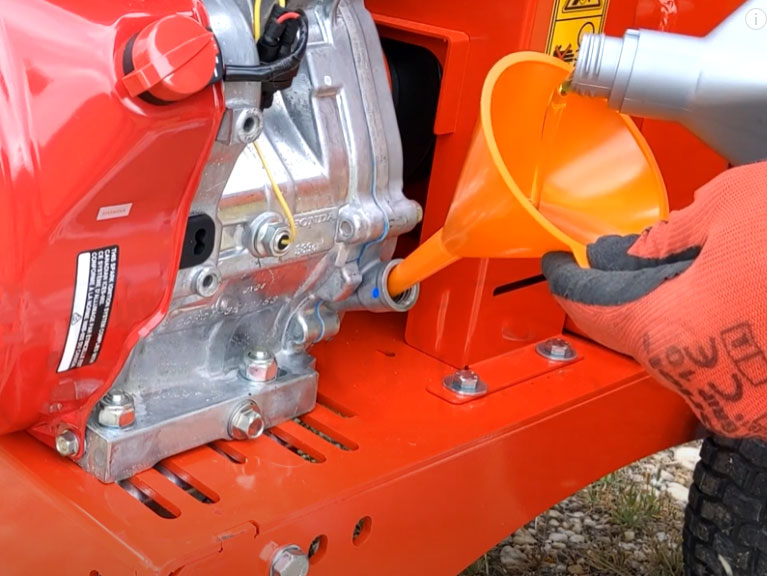

Similar to fuel renewal, the same applies to engine oil.

By lying still with the machine, it will also have lost most of its lubricating properties.

Advice: Engine oil should be changed at least once every year or every 50 hours.

The type of oil to be used, the ideal renewal frequency and the replacement procedure are always indicated in the machine’s instruction manual.

Equally important to changing the engine oil is its regular checking and eventual topping up, regardless of whether the shredder is being used.

To check the engine oil level, simply remove the cap and check the dipstick.

1.3 Air filter check

Another very important part for the proper operation of the combustion engine is the air filter.

This is typically located on one of the sides of the engine, shielded by a protective cover, and filters out all particles and debris that could end up in the engine.

In the process of re-commissioning the machine after storage, its condition must be checked and cleaned of any accumulated dust and dirt.

When possible, simply cleaning it may suffice.

A good example is the picture beside, where one can see a filter that is a bit dirty due to working sessions, though still in excellent condition, thus not needing to be replaced.

If the air filter is found to be excessively worn or damaged, it must be replaced.

This replacement operation is fairly simple to perform, but since it involves one of the main elements of the engine, let’s have a closer look at all the necessary steps.

How to replace the air filter of a shredder?

- The protective cover must first be removed;

- At this point, the filter can be removed and replaced.

This may be fixed using a bolt or clamping, which must first be unscrewed. - Once the new filter is in place and the retainer has been re-attached, the protective casing can be refitted.

Both oil bath and dry filters can be used. In the case of an oil bath filter, the oil must be checked and replaced if necessary.

1.4 Spark plug check

Similarly to the air filter, the condition of the spark plug should also be checked if the shredder has been out of service for a long time.

Using spark plugs in optimal condition is crucial for proper engine operation, but also for smooth, trouble-free starts.

Again, there can be two alternatives:

- A dirty spark plug or perhaps with slight fouling, but in good condition.

In this case, the spark plug can be cleaned using a brush with stiff bristles to remove fouling and a rag soaked in oil for final cleaning; - A damaged or a damaged spark plug must be replaced.

Replacing them is not a particularly complex process, but still requires precise steps to be performed correctly.

Let us see what these steps are.

How to replace a shredder spark plug?

- Once the spark plug is located, remove the pipe;

- A jointed spanner is required to unscrew the spark plug;

- Once removed, it can be replaced with a new one.

- The last step is to fasten the new spark plug.

1.5 Connecting the battery

As with most machines with an internal combustion engine, in case of prolonged downtime, it is always recommended to remove the battery from the machine and store it in a suitable place for the duration of the downtime.

In the chapter on storage will specifically address why the battery should be disconnected and especially how it should be maintained.

Let us now try to summarise the correct procedure for both the scenario of reconnecting the battery after removing it and for that in which we have left the battery connected to the machine for a long time:

- If the battery has been disconnected and stored properly, simply place it back into its compartment and check its charge;

- However, if the battery has been left plugged in the entire time, it must first be recharged, as it will be completely dead.

Once this is done, check that it is working properly, as batteries that remain uncharged for a long time tend to lose all their functionality and often need to be changed.

1.6 Machine inspection and cleaning

This stage depends very much on how we have carried out the storage before or in the previous season.

We will see in the dedicated chapter on maintenance for storage, the correct procedure to follow. If all steps have been properly carried out for this phase, the machine will be in optimal condition, and it will not be necessary to clean it of any accumulated residue.

Therefore, one single check pass may be enough to verify the integrity and proper functioning of the various parts of the machine.

1.7 Blade check

As well as cleaning and the general condition of the machine, check the cutting blades, their condition and wear.

Well-sharpened blades are very important for an effective shredding performance of the bio-shredder, so their condition must be checked regularly, sharpened or replaced when necessary.

At this stage, therefore, it is important to first perform a visual check for a first check on their condition.

The disc is generally easily accessible, to allow this operation to be carried out in the best possible way.

The blades can be single- or double-edged:

- In the first case, resharpening should be carried out on the wet stone or with the water grinding wheel, trying to maintain the cutting angle on the blade.

- In the case of double-edged blades, the blade can be turned, with the part of the blade that has not been used so far turned to the working side.

This postpones the sharpening of both sides to a later step.

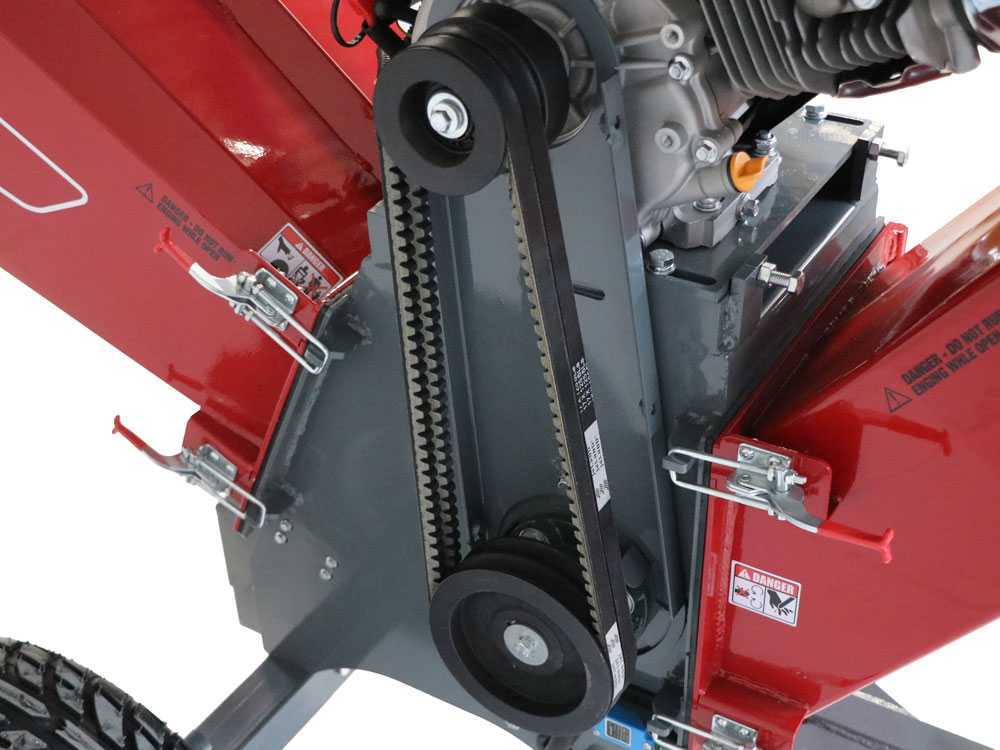

1.8 Inspection of drive belts

Last but not least, there is the drive belt check, which, like the various components linked to the internal combustion engine, is a fundamental part of the shredder.

This too is housed under a guard, to protect it from residues and twigs during operation.

The belts may have loosened after the period of standstill, so the belts must be adjusted to the correct tension.

Belt adjustment:

- Remove the transmission casing;

- Check that the belts are pulled tight enough but not too much;

- Perform the tensioning operation if specified in the manual;

- Reinstall the transmission protection casing.

It is important not to over-tighten the belts so that they slip upon impact with debris or other residue.

If they are too cracked or damaged, they must be replaced.

Belt replacement:

- Remove the transmission casing;

- Loosen the nuts at the base of the engine and move it slightly;

- Replace the belts, always following the instructions in the manual;

- Set the engine back to the working position and tighten the locking nuts;

- Reinstall the transmission protection casing.

2. Routine maintenance

In this chapter, on the other hand, we look at all the maintenance work to be carried out regularly on both the shredder and all its components.

Routine maintenance in fact includes both a simple check of the correct functioning of the various parts of the machine, and cleaning and maintenance of the engine, especially in the case of an internal combustion model, which must be carried out regularly throughout the operating season, all the more so if the machine is used frequently.

We can summarize these operations as:

- General cleaning;

- Air filter inspection;

- Engine oil check;

- Periodic interventions.

2.1 Routine and non-ordinary cleaning

Regular maintenance and cleaning of a shredder is essential to avoid breakdowns and ensure optimum performance.

Routine maintenance operations of a shredder are:

- Shutting down and securing: First, make sure that the machine is switched off or disconnected from the power supply in the case of an electric model.

- Debris removal: use a brush to remove freshly shredded material from blades and internal areas.

An air compressor can also be used to blow away debris from hard-to-reach areas. - Blade cleaning: Degreasers or sanitizing detergents can be used to clean the blades.

Blade protection: Apply a brush stroke of oil to the blades to protect them from oxidation; - General machine inspection: Visually inspect the main parts of the machine for damage or wear.

Non-ordinary cleaning, on the other hand, must be carried out at least once or twice a year depending on the frequency of use of the shredder and is often associated with a subsequent period of machine standstill.

These are more demanding and thorough operations that require more time and specific equipment.

Non-ordinary cleaning:

- Disassembly: Use wrenches to remove the main parts of the machine, such as the hopper and blade disc.

- Deep clean: Clean all disassembled parts with specified products and dry them thoroughly with a cloth.

- Washing of the different parts: Wash all parts, inner and outer, paying attention not to get the engine and adjacent elements wet.

2.2 Air filter check

Another routine maintenance step, also closely linked to the proper functioning of the engine, is the inspection of the air filter.

The air filter must be periodically checked to ensure that it is clean enough and free of the residues from work sessions.

Oil-bath filter: The oil must be checked for dirt and, if necessary, replaced along with washing the filter.

How to clean the air filter of a shredder?

Cleaning an air filter can be carried out by simply shaking it properly to remove dust and dirt, or by blowing it out with the help of a compressor.

2.3 Engine oil check and topping up

The engine oil should be checked periodically and topped up if necessary to ensure proper operation of the combustion engine.

Top-up frequency and the specific type of oil to be used is indicated in the machine manual.

How to check the engine oil level of the shredder?

To check the oil check, simply unscrew the container cap and remove its dipstick.

It is essential to keep the oil level between the minimum and maximum marks on the dipstick, because too low a level would cause poor lubrication of the various components, while too high a level could create air bubbles.

2.4 Periodic interventions

Let’s sum up all the periodic operations to be carried out to ensure maximum efficiency of the machine and guarantee safety during use.

| Interventions | First 8 hrs | Every 8 hrs | Every 40 hrs | Every 12 months | At the end of each session |

| General machine check | Yes | ||||

| Bolt and screw tightening | Yes | Yes | |||

| Check various parts of the combustion engine | Yes | ||||

| Cutting system check | Yes | ||||

| Machine cleaning | Yes |

3. Operations before storage

In this chapter we also include engine-related work, which must be carried out when servicing a petrol-powered shredder, as these are the most common models and also involve the greatest care precisely because of the engine and all its related components.

For electric shredders, maintenance upon storage is easier and faster.

In case of a long period of machine standstill, the maintenance operations to be carried out are:

- Cleaning the machine;

- Emptying the tank;

- Removing the spark plug;

- Disconnecting the battery;

- Machine body lubrication;

- Storage.

3.1 Cleaning the machine

Before an extended standstill, one can remove the front hopper and use compressed air to blow the inside of the machine, where the rotor is located, to clean it of any residue that may have accumulated during the season.

At the same time, check the general condition of the machine for damaged or excessively worn parts.

Therefore, one should avoid leaving a dirty machine, like the one in the picture beside, for a long time.

3.2 Emptying the tank

In the case of a petrol-powered shredder model that will be stored and not used for an extended period of time, it is also essential not to leave the residual fuel from the season in the tank.

Advice: Normally there is a specific screw on the carburettor to carry out this operation.

Fuel that has been left unused for a long time tends to lose all its lubricating properties.

Therefore, using fuel that is weeks or even months old, which has been left in the machine since before storage, can cause very serious damage to the engine and all its related components.

3.3 Removing the spark plug

Another key step in the case of an internal combustion engine machine is to disconnect the spark plug should there be a long standstill.

Once the spark plug has been removed, it is recommended to pour a teaspoon of oil into its housing, so that it is always well lubricated throughout the storage period.

3.4 Disconnecting the battery

Before a long standstill, it is important to unplug the battery from the shredder.

Even if it is not in use, the battery always remains slightly under tension and will eventually run down over time.

Left uncharged for a long time, it tends to lose all its functions and needs to be changed.

The ideal procedure is to unplug it from the machine, store it in a dry, sheltered place and keep it connected to a charge maintainer.

3.5 Machine body lubrication

Apply lubricating oil to the shredder body, which remains stationary for a long time and is exposed to rust and wear.

3.6 Storage

Finally, as a last step, you can proceed with the storage of the machine, which should be left in a dry and closed area, even better if protected by a cover.

All instructions provided in the manual for the respective engine, either petrol or electric, must be carefully followed.

Unplug the machine in the case of an electric model

4. What is needed for maintenance?

We have seen in the previous chapters all the various maintenance operations planned for the main phases of the season, but what are all the necessary items to carry them out?

For the proper maintenance of shredders:

- Engine oil: Which must be regularly replaced and checked to allow it to perform its lubricating action;

- Spark plug replacement kit, which includes not only a replacement spark plug but also a special spanner for removing it: The kit should include a jointed spanner to screw and unscrew the spark plug.

This can come in different sizes and fittings according to the various spark plug models; - Spare blades: New cutting blades to be fitted in the machine in case of damage or excessive wear;

- Spare drive belts: Back-up transmission, for potential failures.

- Spare air filter

Those listed above are the necessary items to carry out all the maintenance work seen above, but what about clothing?

The maintenance of such demanding machinery as a shredder also requires appropriate clothing to allow these tasks to be performed safely.

Thus, essential items for maintenance are:

- Protective gloves;

- Safety goggles.

Especially when cleaning the various parts of the machine, there can be very stubborn dirt and wood residues. Wearing gloves and protective goggles will prevent residues from accidentally getting into your eyes, incurring cuts or irritation.

5. Frequently asked questions from our customers

Single-edged blades can be resharpened on a wet stone. In the case of double blades, however, it is possible to reverse them.

One of the most common operations is composting.

A powerful 22 HP combustion engine can reach 3600 rpm.

Choose a model according to your needs, also considering all the related maintenance.

The branches to be shredded are fed through a hopper and pass through the shredding chamber, where motor-driven blades chop them finely.

Twigs, leaves, pruning waste and garden residues can be fed in.