A complete guide to purchasing bottling machines, with all their features.

The Guide to Choosing the Best Bottle Filling Machines

Comprehensive and Edited by the Real Experts in Oenological Equipment

The bottling machine is a device that helps and speeds up the process of filling bottles and containers. It is a very handy tool for both the private consumer and the small company in the agriculture and food industry that needs help with medium amounts.

There are therefore different types of bottling machines, and in this guide we will focus on the most commonly used models, suitable for both hobby and professional use.

CONTENTS

1. Introduction

A bottling machine is suitable for transferring and bottling the most common food liquids, from wine, oil, beer and milk to tomato sauce and fruit juices. Some models are equipped with special kits and fittings to meet multiple requirements, which may vary depending on the container or liquid to be transferred.

For this reason, there are several types that differ mainly according to their filling process, which can be:

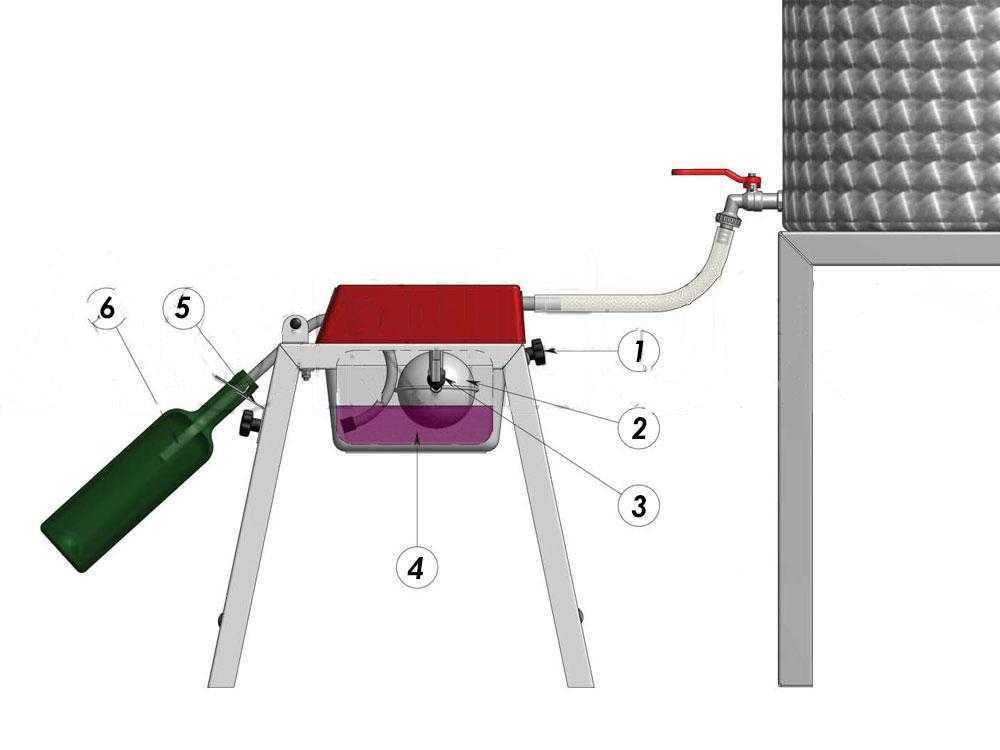

2. Manual gravity bottling machine

- Float height adjuster

- Float

- Inlet pipe valve

- Filler tank

- Bottle holder

- Filling spout

Manual bottling machines are the simplest machines on the market, since they are mechanical and do not need to be powered either electrically or by other devices. They’re operated by gravity, i.e. by the principle of communicating vessels.

It consists of a tank which is to be filled with the liquid to be bottled through a container placed higher up than the bottling machine, in order to make use of the liquid fall. The tank is connected to one or more fittings in order to fill several bottles at the same time. Additionally, the spout valve which is placed in the bottle blocks the flow of the liquid once the bottle is filled.

This machine is optimal for those who do not have large daily volumes to decant and can be used with any type of container, be it glass, plastic or tin.

Glass bottles

Plastic containers

Tin can

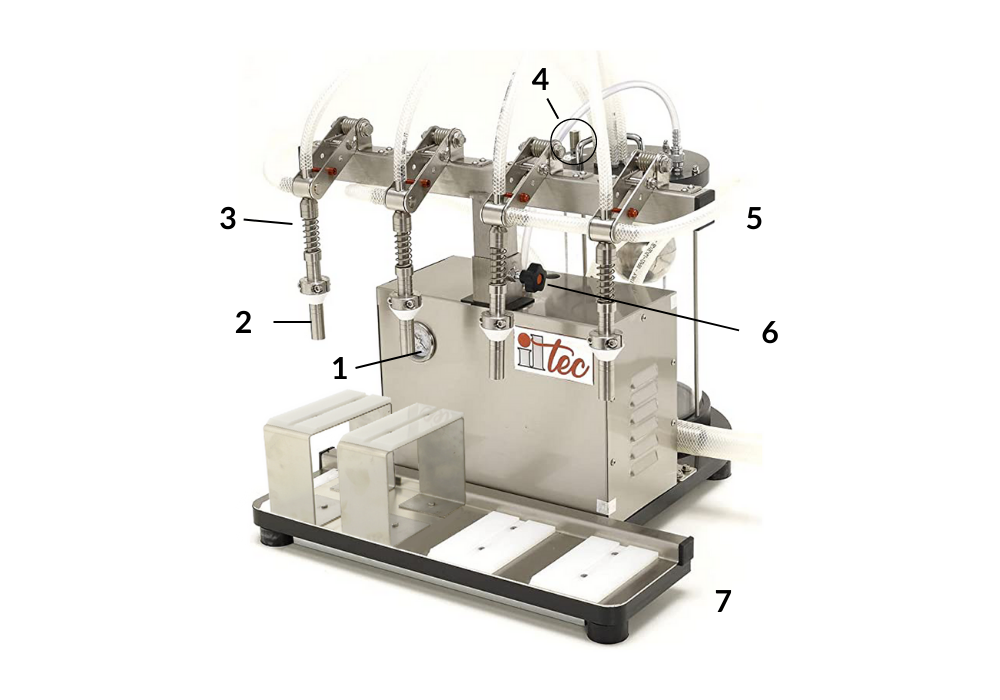

3. Electric vacuum bottling machine

- Specific spout for bottling Opera bottles

- Filling speed adjustment knob (vacuum level can be set at maximum for dense, full-bodied or unfiltered wines, at minimum for sparkling wines to avoid foam build-up)

- Arm height adjustment system (the joint can be raised and lowered by rotating the knob)

- Spout stroke (screwing and unscrewing the ring nut allows one to adjust the filling level of the liquid in the bottle)

- Bottle clamping system (the arm spring allows the spout to apply significant pressure on the bottleneck, thus preventing the liquid from spilling out)

- Adjustable jointed arm

- Vacuum chamber

Electric bottling machines are compact, tankless machines that use a pump to create the vacuum needed to draw liquids from a container. In this situation, since gravity operation is not employed, it does not need to be above the machine.

The vacuum operation allows liquids to be transferred from the container to the bottle without shaking, thus ensuring natural flow and avoiding altering the product’s properties. Furthermore, only glass containers must be used with this machine, as the vacuum system is not suitable for saggy containers such as plastic or tin

This type of bottling machine can feature one or more outlet spouts, either plastic or stainless steel, which can be of different types depending on the container or liquid to be bottled:

- Wine

- Oil

- Beer

- Liquids up to 80 degrees

- Opera bottles

- Mignon bottles

- Small jars

- Multipurpose

Kristal Kit for liqueurs

Kit for opera bottles

Spout for mignon bottles

Kit for jars

Another important accessory is the inlet filter system for decanting oil or wine: the filter, which can be made of stainless steel or fibreglass and have different filter diameters, is re-usable multiple times.

Filter holder

Stainless steel filter cartridges

Glass fibre filter cartridges

4. Semi-automatic pneumatic bottling machine

The semi-automatic models have almost the same specifications as the electric ones, and the main difference is that they are pneumatically powered by compressed air, so they work by connecting them to a compressor.

- Vacuum meter (or vacuum gauge, a tool for measuring fluid pressure)

- Spout

- Spout stroke

- Filling speed adjustment knob

- Recovery tank

- Arm height adjuster

- Bottle deposit tray

The small, light-weight models are extremely easy to handle, and the high-quality materials qualify them for use according to European standards. Additionally, the machine is equipped with an Autostop system that halts the bottling when the targeted level is reached.

Compressed air bottling machines not only have the ability of filling several bottles simultaneously, but are also equipped with several regulation systems which allow them to:

- adjust the height of the spout to fit different bottle and container sizes;

- decide the filling level, which then turns automatic once set;

- adjust the bottling speed.

Height adjuster

Fill level regulator

Speed controller

An important thing to keep in mind when using this machine is not to bottle carbonated food liquids exceeding 80°. Besides that, depending on the models, they are suitable for:

- Wine

- Oil

- Beer

- Vinegar

- Cider

- Non-viscous liquids

- Tomato sauce

Bottle of wine

Bottles of extra virgin olive oil

Bottles of beer

Bottle with tomato sauce