A comprehensive guide to purchasing the best tractor-mounted mist blowers, with lots of useful information on how they work and their main features.

The complete Guide to help you choose the Best Tractor-Mounted Mist Blowers

Completed and edited by real Tractor Agricultural Machinery Experts.

CONTENTS

1. Introduction

Tractor-mounted mist blowers are the most effective and professional choice for pesticide treatment in orchards, olive groves and vineyards. They are used and operated through an agricultural tractor, which can incorporate them into its structure via the classic three-point hitch or tow them.

They are able to perfectly nebulise the product to be spread, creating very small, dense droplets that allow even distribution on all surfaces.

The main categorisations we can make for these machines are based on their capacity and the method of use through the tractor. In fact, we can find:

- Tractor-mounted Agricultural Mist Blowers, 200 L;

- Tractor-mounted Agricultural Mist Blowers, 300 L;

- Tractor-mounted Agricultural Mist Blowers, 400 L;

- Tractor-mounted Agricultural Mist Blowers, 600 L;

- Trailed Tractor-Mounted Mist Blowers.

2. Types of Mist Blowers

As mentioned, among the main aspects that differentiate tractor-mounted mist blowers, is the way they are transported by the tractor.

Mist blowers can be “tractor-mounted” or “trailed”, but what do these two terms mean?

Tractor-mounted models, are integrated with the tractor through a special steel frame and a three-point hitch, while trailed models are connected to the tractor through a length-adjustable drawbar and towed by the agricultural vehicle, they are also equipped with sturdy tyres for better mobility.

2.1 Tractor-Mounted Mist Blowers

Tractor-mounted mist blowers are the most common category in the crop protection industry; they are attached to the tractor via hot-dip galvanised steel structures, and are particularly resistant to rust.

They are connected to the tractor through a three-point hitch using steel pins located at the rear of the machine.

They can be divided into several models with:

- Front suction: The air flow is redirected to the rear of the intake area;

- Tower suction: The most precise suction system. It is preferred for treatments of fruit plantations, vines and olive groves, as it directs the product through extremely precise and uniform air streams.

- Rear suction: The standard ventilation system, the most economical and functional version;

Front and rear suction, are similar in terms of working methods and product distribution, however, in front suction, the machine draws air from the front of the turbine, avoiding contamination with the chemicals used.

The air flow and the plant protection mixture are directed to the rear of the sprayer’s suction area, avoiding the re-suction of the mixture and also limiting the deposit of leaves and debris towards the flow suction grid. With this type of suction, the flow of the atomised product is distributed more efficiently, without risking contamination of neighbouring crops and away from the operator, providing greater protection for those on board of the tractor, who will not breathe in the product used.

2.2 Trailed Mist Blowers

Trailed mist blowers are machines that are connected to the tractor via a three-point hitch as well, but unlike mounted models, they are towed by the agricultural tractor.

The main advantage of using this type of mist blower lies in the extensive ground coverage that is achieved: thanks to its larger size and ability to be towed, the mist blower is able to cover large areas in a short time.

The large wheels also allow it to be coupled to less powerful machines and still provide good grip on uneven and rough surfaces.

3. Composition

The main parts that make up an agricultural tractor mist blower are: the fan, the tank, the control unit and the tractor pump.

3.1 The fan

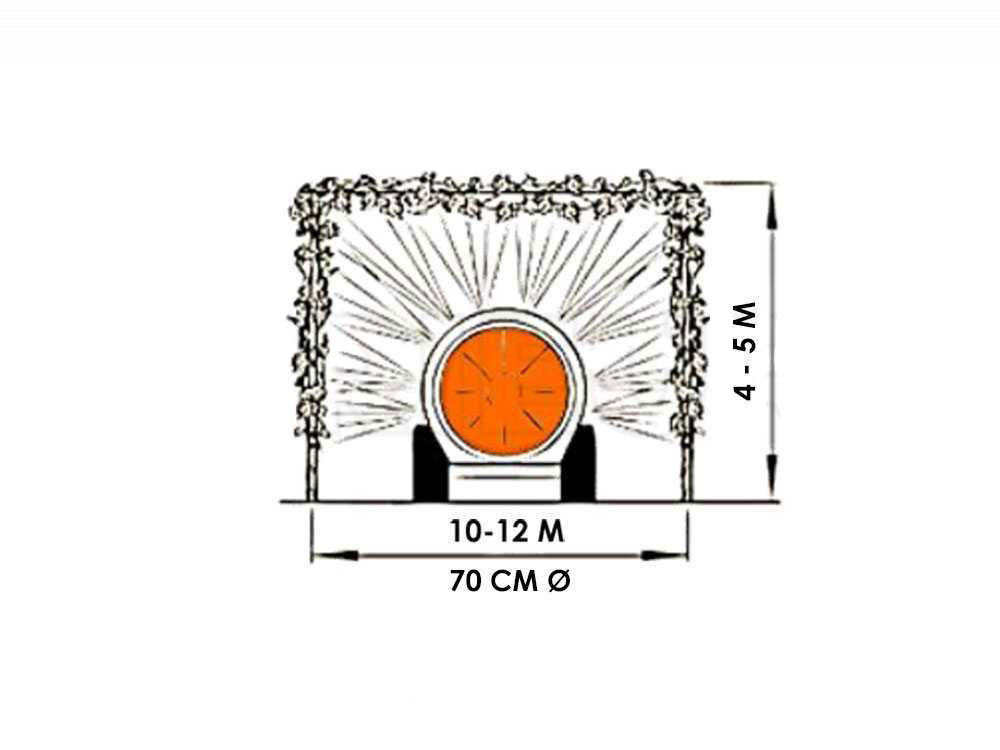

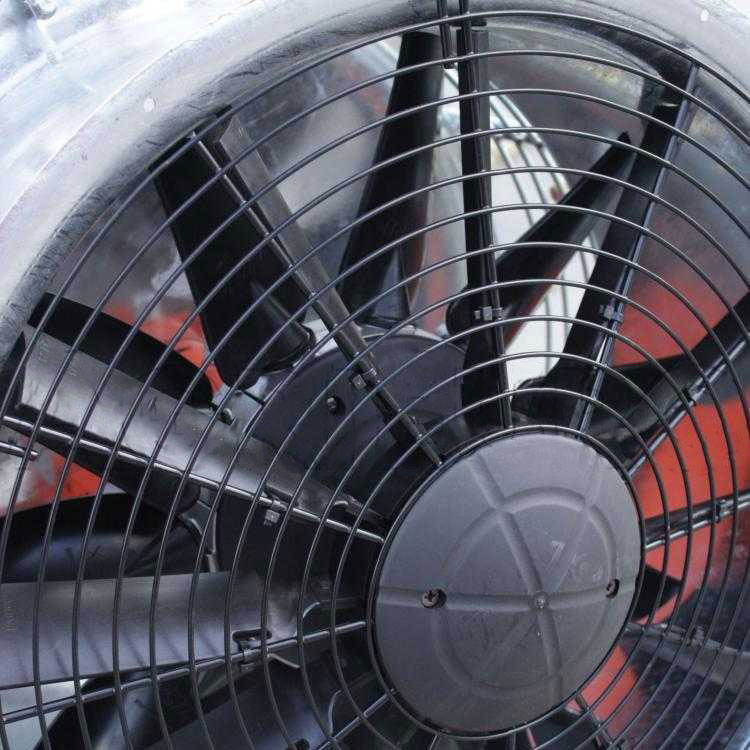

The size of the fan is one of the most important elements of a mist blower, as it determines the power of the air jet and the fineness of the atomising. A larger amount of air, in fact, means greater capacity of the machine to perform operations at greater heights and distances.

Fans are adjustable and provide excellent weather resistance. They distribute the product evenly over the whole plot of land. Their diameter can measure 60 cm at least, up to 80 cm.

Mist blowers with a 60 cm diameter fan are recommended and generally used for hobbyist work.

With a 70 cm diameter fan it is possible to carry out semi-professional work, while fans with larger diameters, such as 80 cm, are used for more professional and demanding work.

| Fan diameter | Level |

| 60 cm | Hobbyist use |

| 70 cm | Semi-professional use |

| 80 cm | Professional use |

The fan unit, as mentioned, is the element that determines the power of the mist blower, that is, the machine’s ability to push the sprayed product in height and width.

Taking an average fan diameter of 70 cm as reference, a mist blower can spread the product up to 5 metres high and 10–12 metres in width.

3.2 Counter-fan system

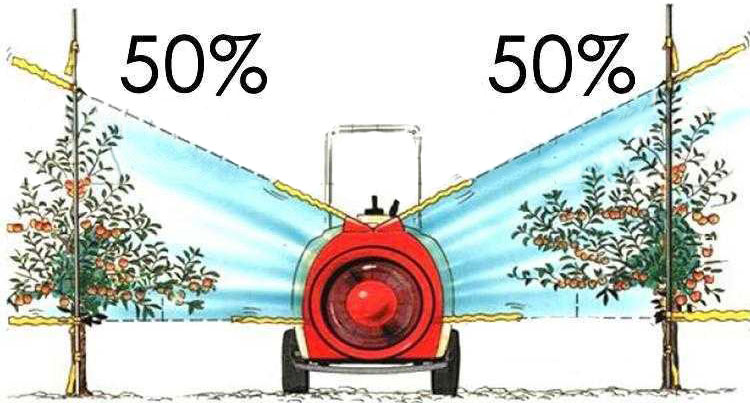

Fans can also be equipped with a double propeller, or more specifically with a ‘counter-fan’ system.

Unlike the classic single propeller system, the fan has a double propeller, where the second one is fixed and has blades with an identical and opposite profile to the one that is in motion.

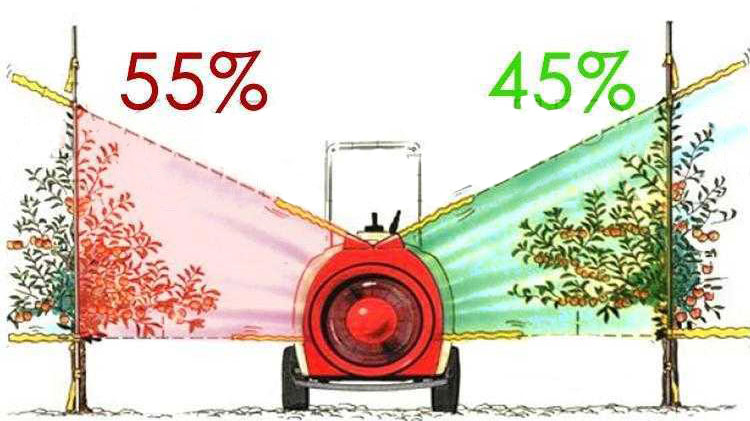

This is a system that can deliver a more even air jet, compared to a classic ventilation systems. With the single propeller fan unit, in fact, the air jet is distributed as follows: 55% on the left side of the mist blower and the remaining 45% on the right side.

Adding the second fixed propeller, on the other hand, balances the air delivery, which is distributed equally on both sides, allowing more uniform treatments.

3.3 The tank

The tank is the container where the mist blower stores the liquid to be distributed on the plants and crops.

It is made of a plastic material like polyethylene, which is very durable and easy to repair.

The capacity of a mist blower ranges from 200 litres in the smaller models up to 1000 litres for the larger ones;

3.4 The control unit

The control unit contains all the main controls and adjustments of the machine:

- Liquid pressure adjustment knob;

- The pressure gauge;

- Open and close pressure control lever: With this lever, it is possible to activate the jets only on the left or on the right side;

- Remote control unit: The control unit is equipped with long cables to enable it to be brought up to the tractor and thus to the driver’s disposal.

3.5 Tractor pump

The pump is used to pressurise the liquid to be sprayed and is operated by the tractor’s power take-off.

Tractor mist blowers are usually equipped with diaphragm pumps: this type of pump is designed to handle liquids with different viscosity levels, can handle chemicals, even particularly aggressive ones, such as those usually used for plant protection treatments. They are very similar to piston pumps, but have membranes on the inside to pump the liquid. This is due to alternating expansions and contractions of the volume of a chamber that increases pressure and triggers the pumping of liquid.

They consist of:

- Typically three or four membranes, ensuring high resistance against the chemicals that are used. Three-diaphragm pumps are used for spraying medium to large crops, while those with four diaphragms are used for treatments with products under high pressure;

- Rubber seals applied to the connecting pipes;

- Transparent plastic tank for visual control of the liquid level;

- Air valve, which directs compressed air and helps move the diaphragm unit;

- Membrane locking system, which prevents contact tearing even with particularly heavy use.

4. Important parameters

Now, let’s look at the most important parameters to take into consideration in a mist blower:

- The capacity of the tank: One of the most important aspects to consider is the maximum capacity of the tank containing the liquid for treatment;

- Maximum spraying height: Indicates the maximum height that the machine can reach when spraying the product;

- Maximum distance: A proportional measure to that of the maximum height, that indicates the maximum horizontal distance that the machine can reach when spraying the product;

- Flow rate: The amount of product the machine can distribute in a precise time frame is expressed in litres per minute (l/min) This parameter varies according to the requirements of individual operations, but we can summarise it in a chart as follows

| Flow rate below 60 l/min. | Low flow rate |

| Flow rate between 60 and 80 l/min. | Average flow rate |

| Flow rate above 80 l/min. | High flow rate |

5. Number of jets

The jets, which atomise and spread the plant protection product, are positioned around the fan rim and are evenly distributed on both sides for equal distribution.

They are directly connected to the tank containing the spray product to be distributed.

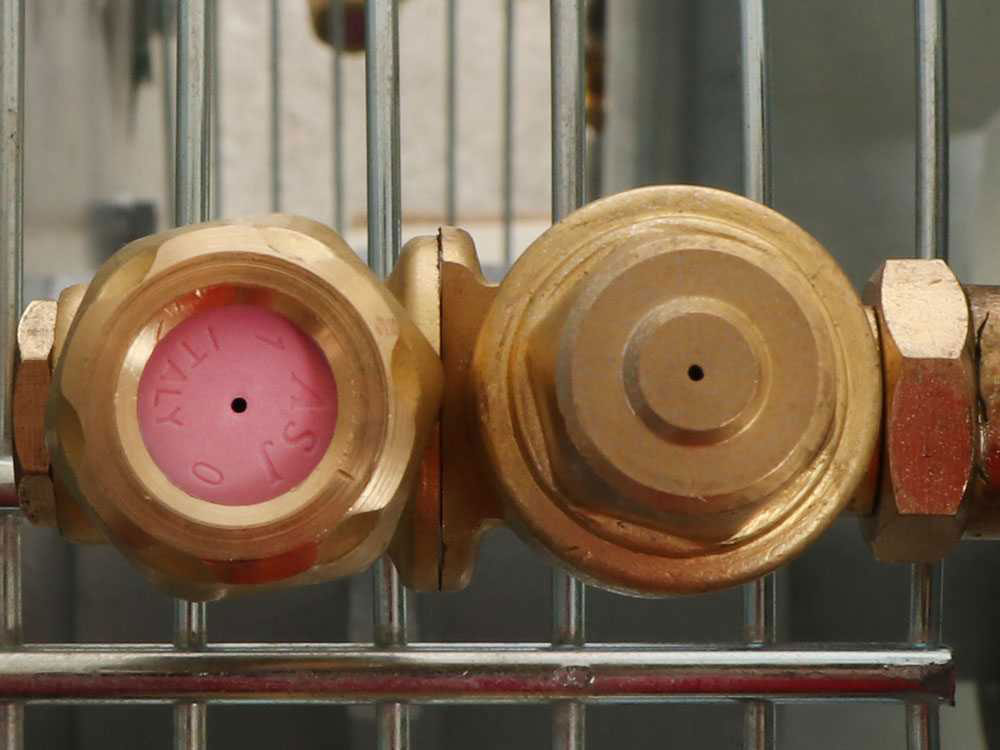

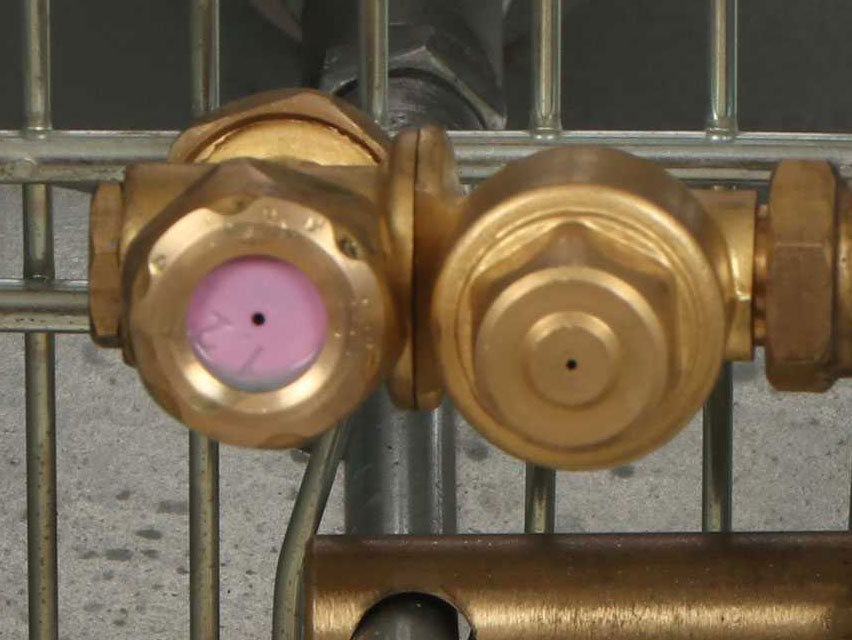

The nozzles can be set to three clicks that match with their positions:

- Nozzle with larger hole, for greater liquid output;

- Central position = closed jet;

- Nozzle with smaller hole, for reduced liquid output;

6. Transmission and fan speeds

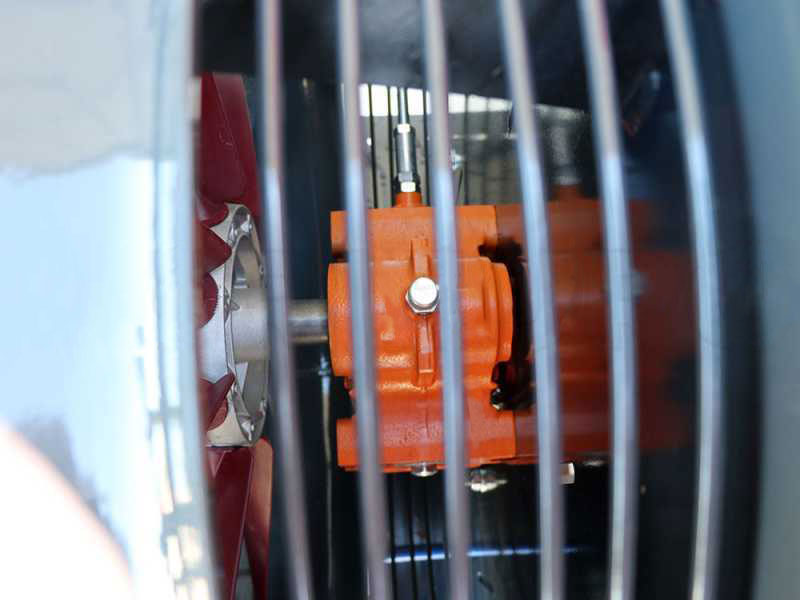

The mist blower transmission is an oil-bath gearbox for great strength and reliability.

The fan movement is controlled by a gear multiplier positioned between the fan unit and the machine’s tank.

Connected to the transmission is a clutch lever, which also allows adjustment of the fan speed, which can be single plus neutral, or double plus always neutral.